Clean rooms often rely heavily on your applications, but used clean rooms are often an effective and more affordable option. Some clean room manufacturers also offer their customers these previously used and refurbished clean rooms to help customers satisfy their application requirements while staying within their budget. Read More…

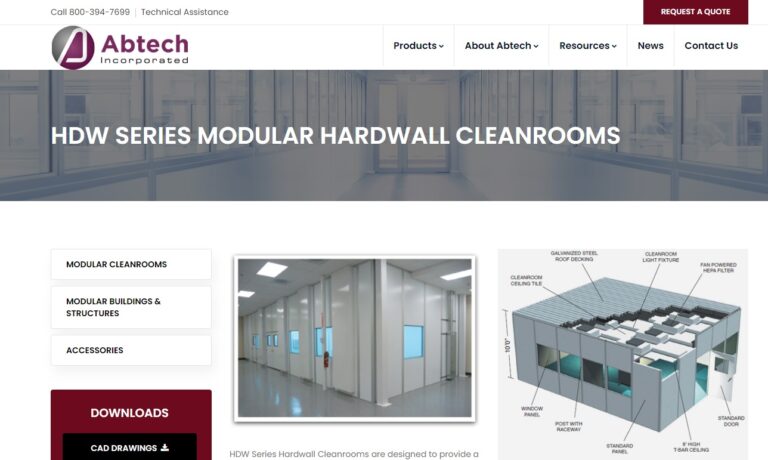

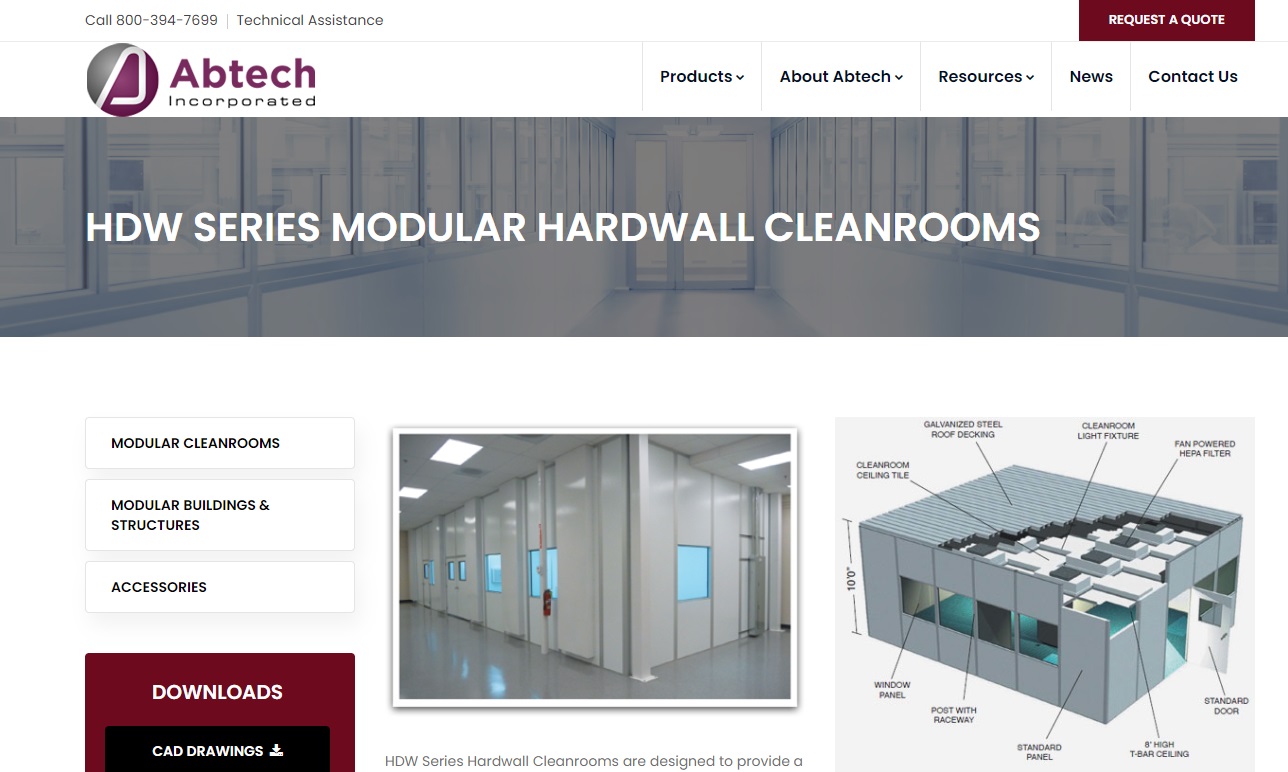

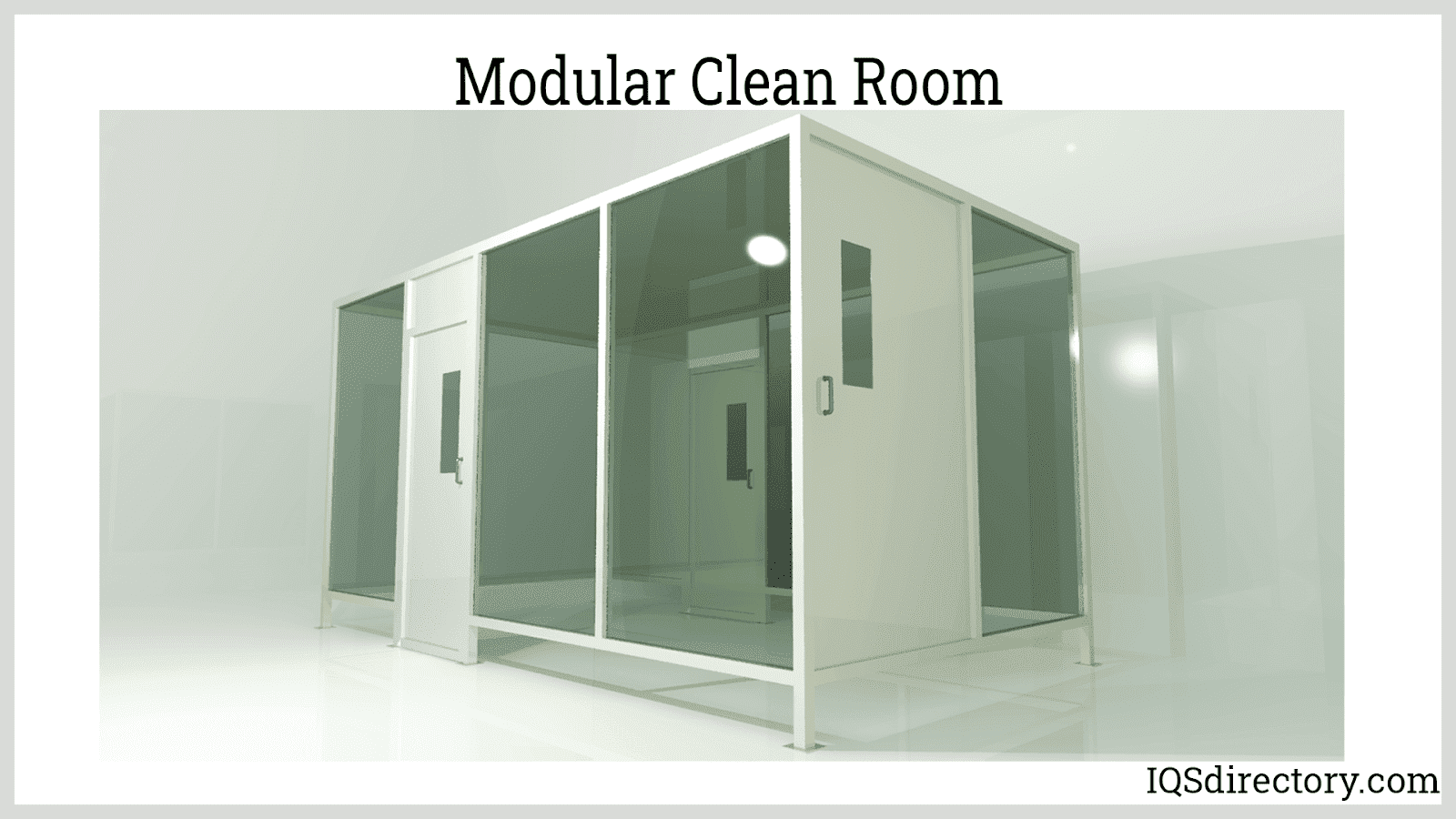

As a manufacturer of clean rooms, including inplant modular offices, exterior steel buildings, guard buildings, fork liftable and crane liftable buildings, multi-level buildings and mezzanines, Abtech offers turnkey installations or packages for install by end user. Our modular structures are constructed of steel, are free-standing & manufactured under strict quality control methods.

For the very best of clean rooms, look no further than Clean Rooms International! We can provide the ultimate in quality, customer service, durability, and unique designs just for you!

Cleanrooms By United is the industry’s premier manufacturer of modular clean room systems. We design, manufacture and install our clean rooms to meet our customers’ unique requirements. The custom, flexible, modular construction of our cleanrooms makes them easy to expand, reconfigure, or relocate as your cleanroom needs evolve.

Atmos-Tech Industries is a designer and manufacturer of cleanrooms and equipment for industries, including health care, pharmaceutical aerospace and automotive.

Our design staff is qualified with over 30 years of clean room experience. Our clean rooms are made from the highest quality materials and use a modular design that can be modified to suit any needs.

Our complete line of clean rooms will meet your needs. We are the experts of the clean room industry and our engineers can work with you to determine which clean room models work best for your business. We offer a variety of softwall, bio-clean, hardwall, and micro-clean options, all of which are manufactured with the highest standards. You will not be upset with our products. Contact us for more ...

Bayside Interiors is able to provide the design, engineering and construction of clean rooms. Bayside Interiors Inc. has been around since 1984. We also specialize in the construction of strut framing systems and facility support systems.

BASX Solutions has been designing and manufacturing truly modular cleanrooms since 1984. These are durable, scaleable, portable cleanrooms and are available in both softwall and hardwall designs. Our products meet the highest industry levels, from Class 100 to 100,000. Call for a free quick quote.

Since 1976, we at Mitchell Technical Sales have been dedicated to delivering excellence in quality cleanroom design, manufacturing, installation, certification, and maintenance. Our journey has been marked by innovation and expertise, ensuring that every project we undertake reflects our commitment to precision and cutting-edge solutions.

Welcome to Cleanrooms USA, where we pride ourselves on delivering unparalleled expertise and innovative solutions in the realm of cleanroom technology. At Cleanrooms USA, we are dedicated to providing cutting-edge cleanroom environments that meet the stringent requirements of industries ranging from pharmaceuticals and biotechnology to electronics and aerospace.

More Used Clean Room Manufacturers

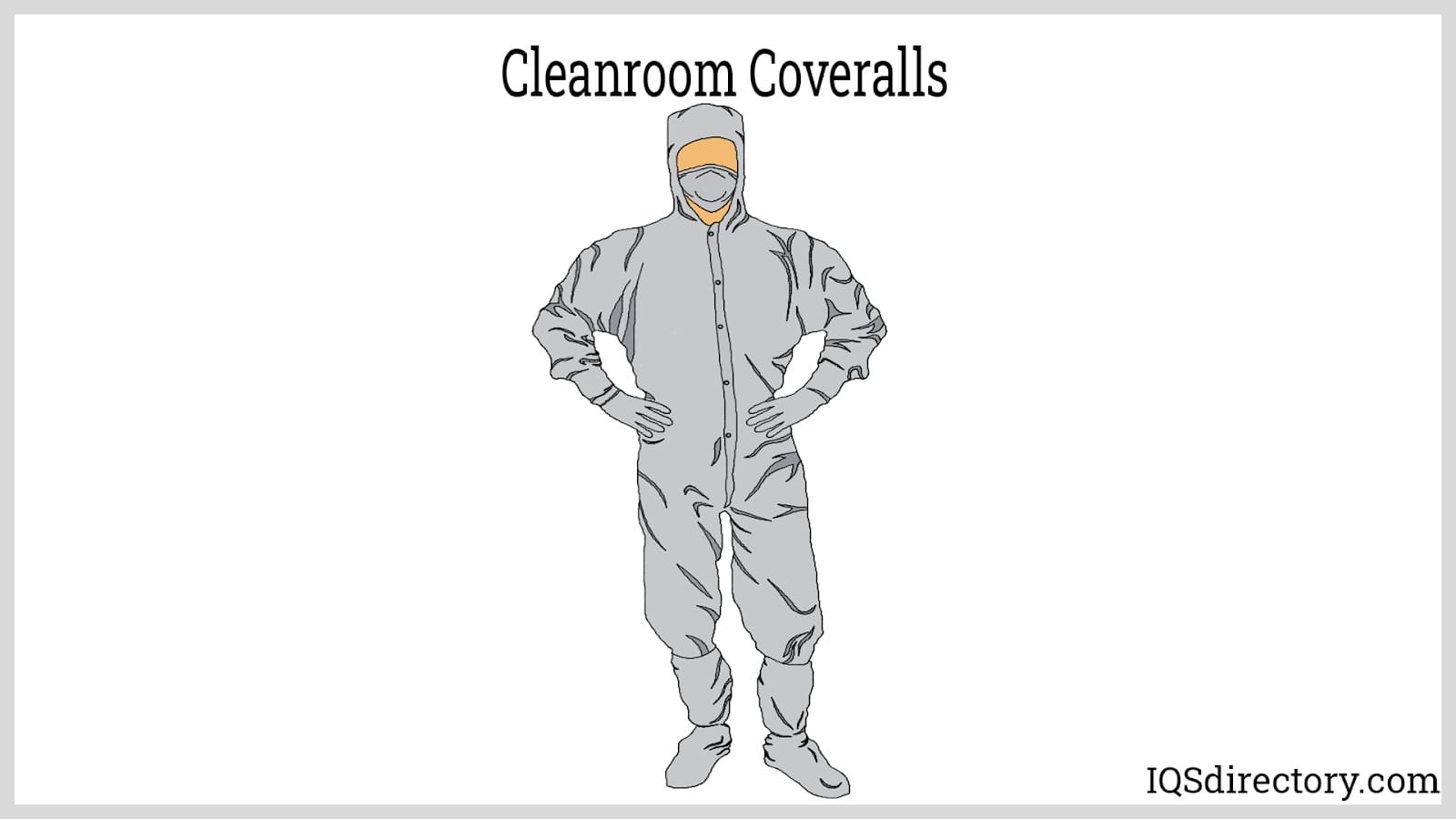

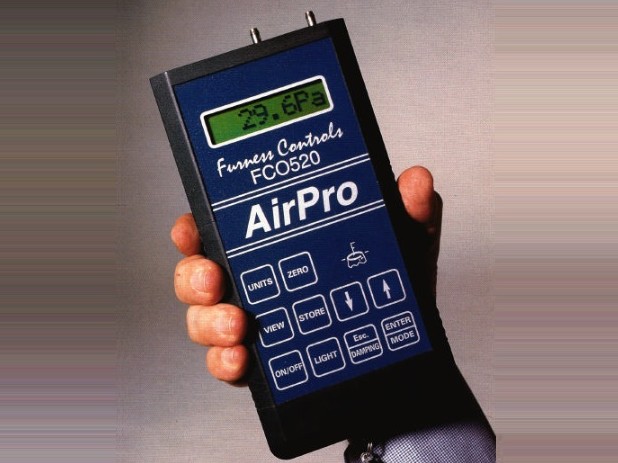

Clean rooms got their start in the early sixties specifically dealing with the control of air flow within a certain area in order to keep air contaminant free during the testing or manufacturing of certain products. This process has evolved and is used in a wide variety of applications from lab experiments to the manufacturing of microchips which require the utmost cleanliness.

In addition to cleanliness, the overall temperature of the room can be manipulated to help maintain ideal environmental conditions during sensitive manufacturing or testing processes. This feature is a must have for applications such as in the computing industry where the slight shift in temperature can cause a product to not function properly.

As clean room technology continues to advance, older clean rooms may be left behind to take advantage of the newer versions. However, used clean rooms can provide much the same functionality as new clean rooms, but may not use the same newer, more advanced technology. When purchasing a used clean room, you are essentially trading the newer, more advanced features of a new clean room for reduced upfront costs.

For many applications that do not require the advanced control features, this trade-off makes perfect sense and is a great cost saving option. On the other hand, it is important to keep in mind that used clean rooms may not have the features you require and may exhibit other issues or problems that come along with prolonged usage.

When purchasing a used clean room, it is incredibly important to carefully consider all of your application requirements. This will ensure that you do not end up with a clean room that does not offer the capabilities you require. For the best results, you should also carefully examine and analyze any used clean room you would potentially purchase so that you can avoid spending money on damaged components and future repairs.

Consult with a used clean room supplier as well as with clean room manufacturers before you make an investment as their insight and suggestions will be incredibly useful in acquiring a solution that most closely meets your needs. There are a lot of options out there and the best way to get the best possible product for yourself is by working with a trusted, knowledgeable, and experienced clean room manufacturer.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services