Technological advances and the development of complex instrumentation have necessitated purified environments to avoid contaminating components and parts from atmospheric particles and bacteria. Clean rooms were developed in the middle of the 20th Century to create the ideal tool for providing conditions for the production, manufacture, and fabrication of modern technological tools and instruments. Read More…

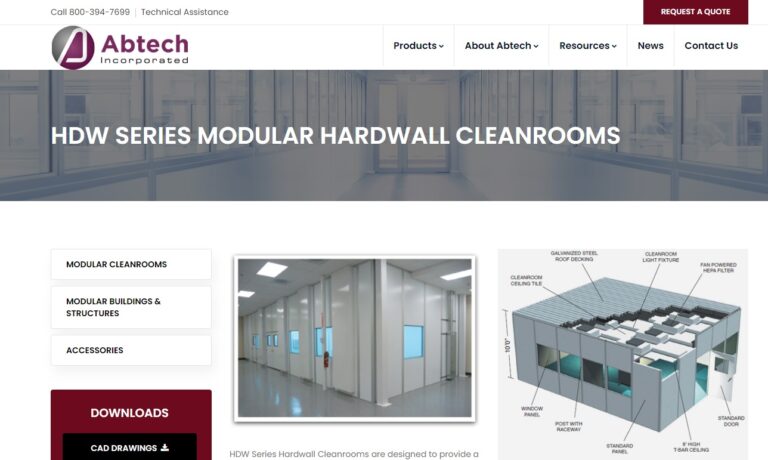

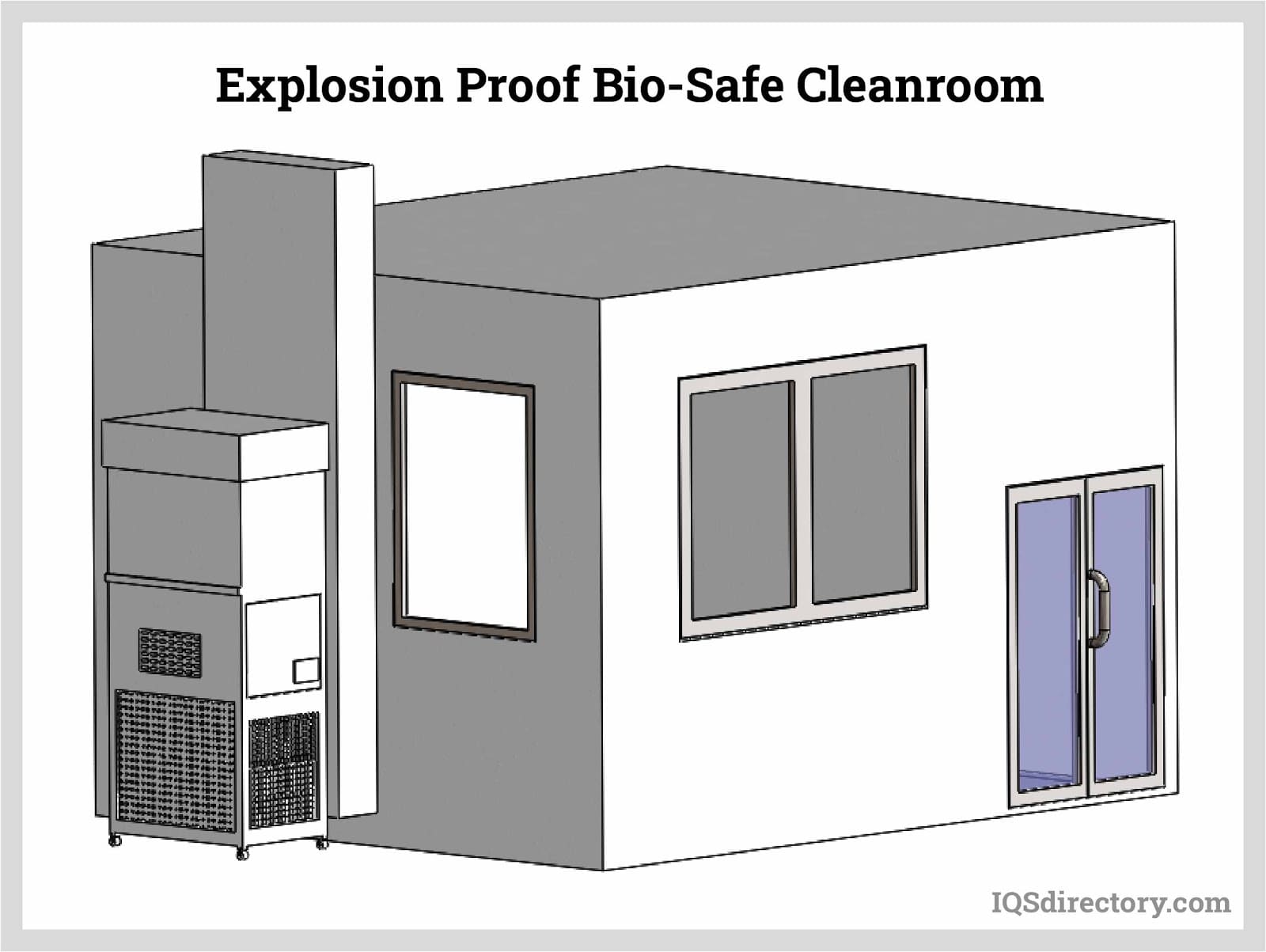

As a manufacturer of clean rooms, including inplant modular offices, exterior steel buildings, guard buildings, fork liftable and crane liftable buildings, multi-level buildings and mezzanines, Abtech offers turnkey installations or packages for install by end user. Our modular structures are constructed of steel, are free-standing & manufactured under strict quality control methods.

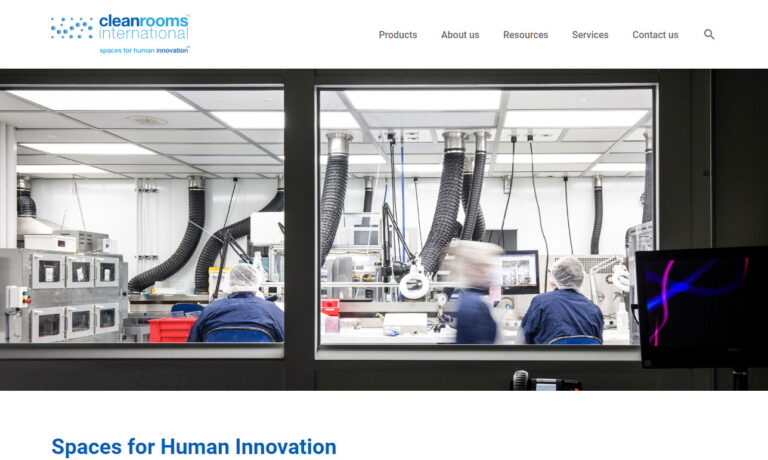

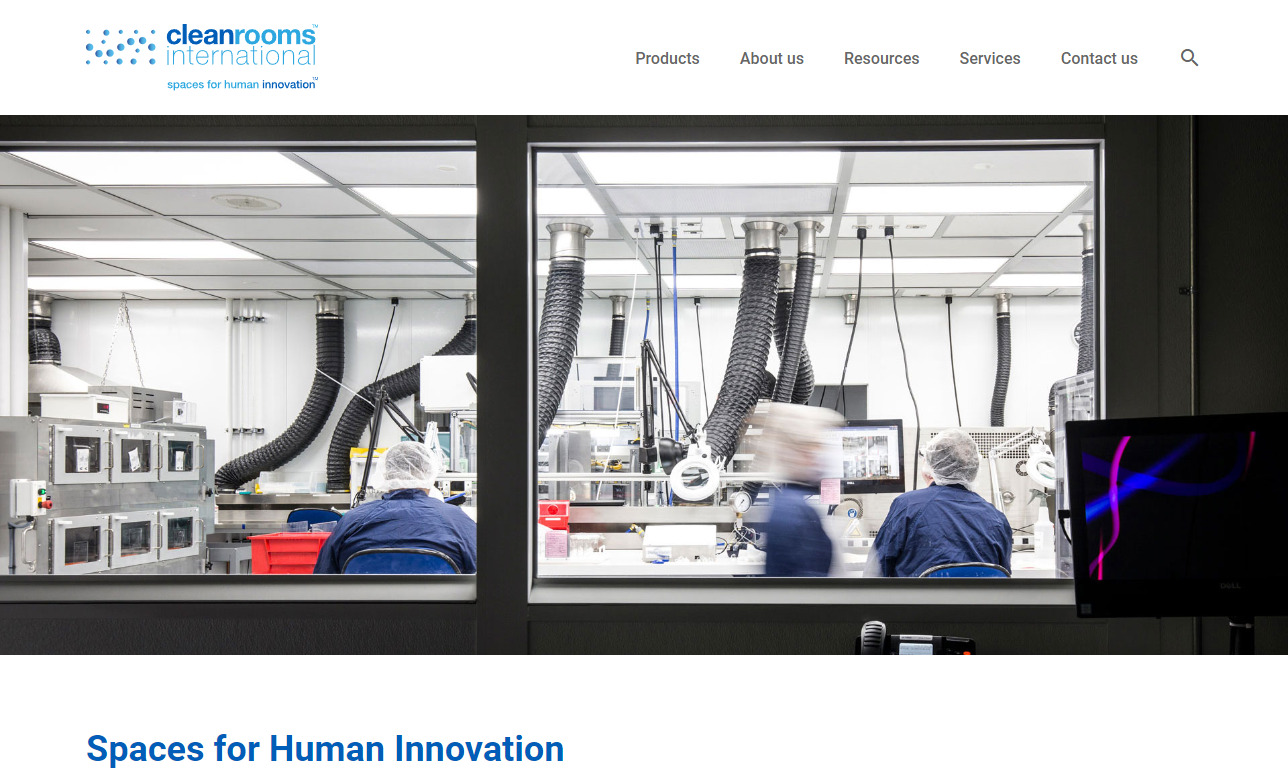

For the very best of clean rooms, look no further than Clean Rooms International! We can provide the ultimate in quality, customer service, durability, and unique designs just for you!

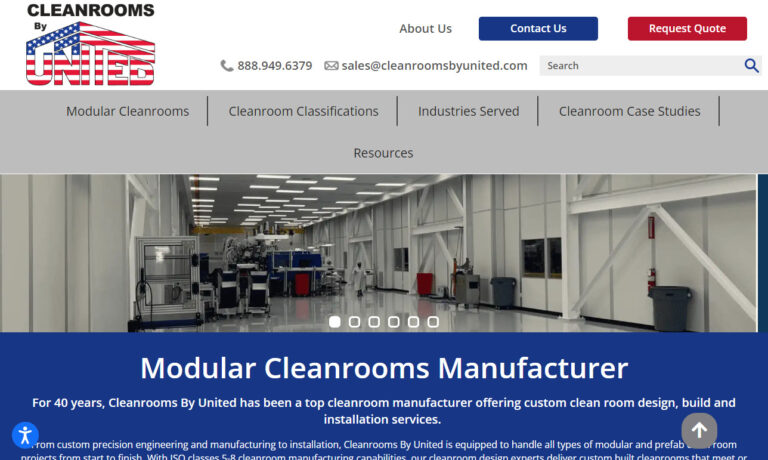

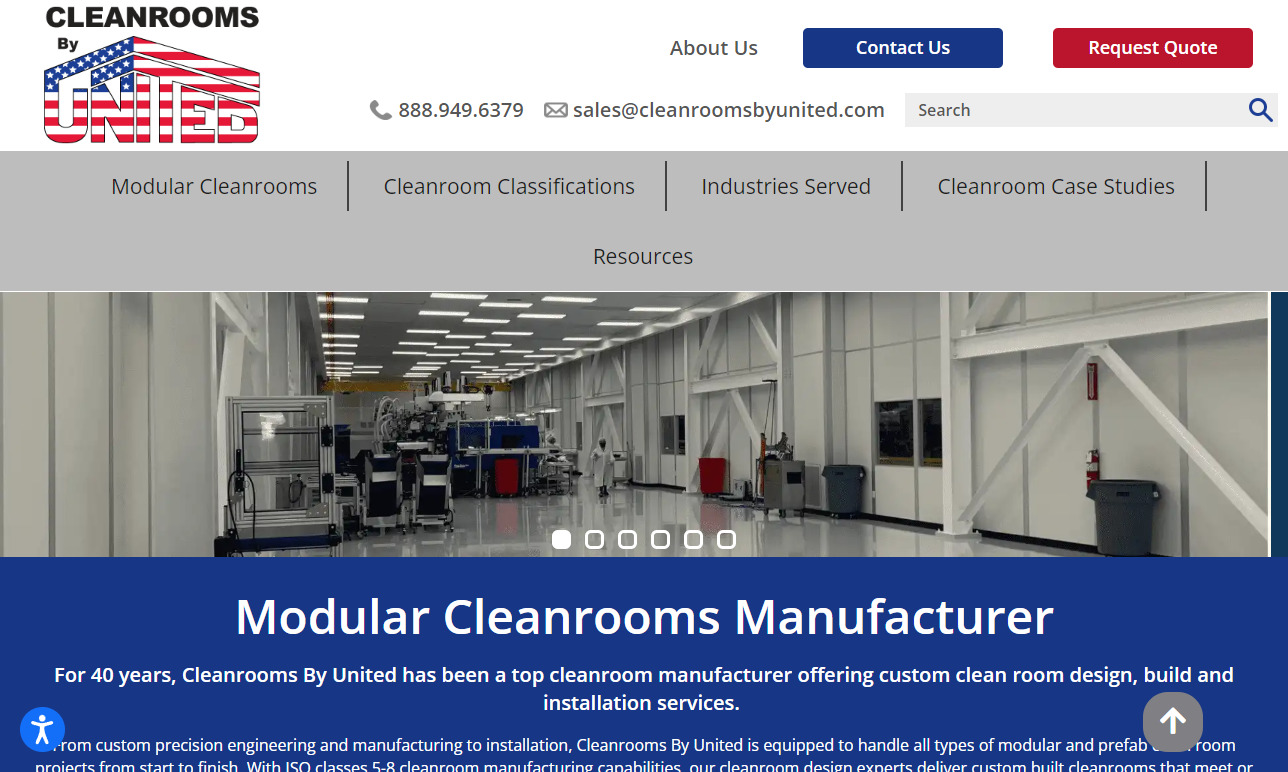

Cleanrooms By United is the industry’s premier manufacturer of modular clean room systems. We design, manufacture and install our clean rooms to meet our customers’ unique requirements. The custom, flexible, modular construction of our cleanrooms makes them easy to expand, reconfigure, or relocate as your cleanroom needs evolve.

Atmos-Tech Industries is a designer and manufacturer of cleanrooms and equipment for industries, including health care, pharmaceutical aerospace and automotive.

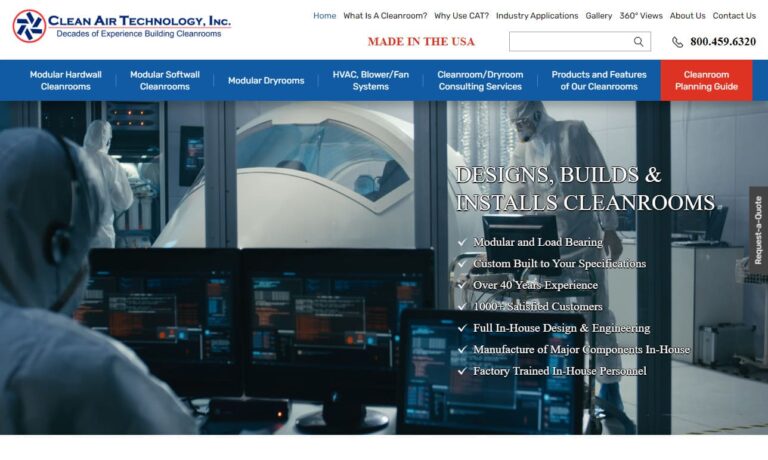

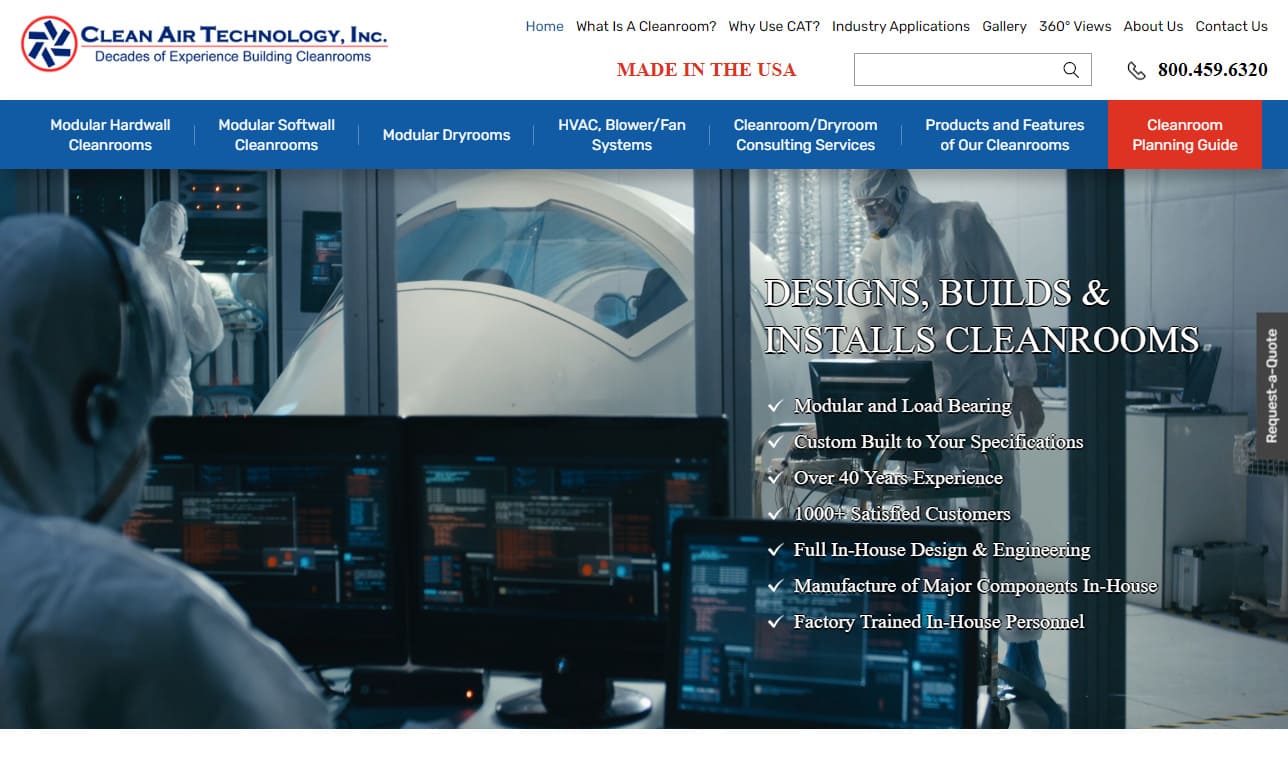

Our design staff is qualified with over 30 years of clean room experience. Our clean rooms are made from the highest quality materials and use a modular design that can be modified to suit any needs.

Our complete line of clean rooms will meet your needs. We are the experts of the clean room industry and our engineers can work with you to determine which clean room models work best for your business. We offer a variety of softwall, bio-clean, hardwall, and micro-clean options, all of which are manufactured with the highest standards. You will not be upset with our products. Contact us for more ...

Bayside Interiors is able to provide the design, engineering and construction of clean rooms. Bayside Interiors Inc. has been around since 1984. We also specialize in the construction of strut framing systems and facility support systems.

BASX Solutions has been designing and manufacturing truly modular cleanrooms since 1984. These are durable, scaleable, portable cleanrooms and are available in both softwall and hardwall designs. Our products meet the highest industry levels, from Class 100 to 100,000. Call for a free quick quote.

Since 1976, we at Mitchell Technical Sales have been dedicated to delivering excellence in quality cleanroom design, manufacturing, installation, certification, and maintenance. Our journey has been marked by innovation and expertise, ensuring that every project we undertake reflects our commitment to precision and cutting-edge solutions.

Welcome to Cleanrooms USA, where we pride ourselves on delivering unparalleled expertise and innovative solutions in the realm of cleanroom technology. At Cleanrooms USA, we are dedicated to providing cutting-edge cleanroom environments that meet the stringent requirements of industries ranging from pharmaceuticals and biotechnology to electronics and aerospace.

More Cleanroom Design Manufacturers

The term clean room refers to a specially engineered and designed environment that has been cleansed of dust, dirt, microbes, and other contaminating particles. To be classified as a clean room, specific standards and conditions must be met, as stipulated by the United States Governments Federal Standards 209 (FED-STD-209E) and the International Organizations for Standardization (ISO).

The description of the standards of the ISO and Federal Standard 209 clearly and concisely defines the conditions a clean room must meet to be classified as a clean room. Adhering to the qualifications is the initial step in the process, followed by determining what classification a clean room meets.

Although the ISO and Federal Standard 209 intend to define the class of a clean room, each organization approaches the issue using a different classification method. For the ISO, clean rooms are classified using a numbering system, beginning with ISO 1 for the strictest compliance with clean room standards and continuing to ISO 9. Federal Standard 209 was published by the Institute of Environmental Sciences and Technology (IEST) in 1963 and was updated in 1992. Its numbering system begins with class 1 (ISO 3) as the most restricted and continues to class 100000.

The designing of a clean room begins with determining what classification is necessary. The primary factor in deciding is based on the size and quantity of particulate matter allowed in the air, which is essential for defining a clean room's classification.

| Maximum Particles/m³ | |||||||

| Classification | ≥0.1µm | ≥0.2µm | ≥0.3µm | ≥0.5µm | ≥1µm | ≥5µm | FED STD 209E Equlvalent |

|---|---|---|---|---|---|---|---|

| ISO 1 | 10 | 2.37 | 1.02 | 0.35 | 0.083 | 0.0029 | |

| ISO 2 | 100 | 23.7 | 10.2 | 3.5 | 0.83 | 0.029 | |

| ISO 3 | 1,000 | 237 | 102 | 35 | 8.3 | 0.029 | Class 1 |

| ISO 4 | 10,000 | 2,370 | 1,020 | 352 | 83 | 2.9 | Class 10 |

| ISO 5 | 100,000 | 23,700 | 10,200 | 3,520 | 832 | 29 | Class 100 |

| ISO 6 | 1.0 x 10^6 | 237,000 | 102,000 | 35,200 | 8,320 | 293 | Class 1,000 |

| ISO 7 | 1.0 x 10^7 | 2.37 x 10^6 | 1,020,000 | 352,000 | 83,200 | 2,930 | Class 10,000 |

| ISO 8 | 1.0 x 10^8 | 2.37 x 10^7 | 1.02 x 10^7 | 3,520,000 | 832,000 | 29,300 | Class 100,000 |

| ISO 9 | 1.0 x 10^9 | 2.37 x 10^8 | 1.02 x 10^8 | 35,200,000 | 8,320,000 | 293,000 | Room Air |

Federal Standard 209 Air Classification System

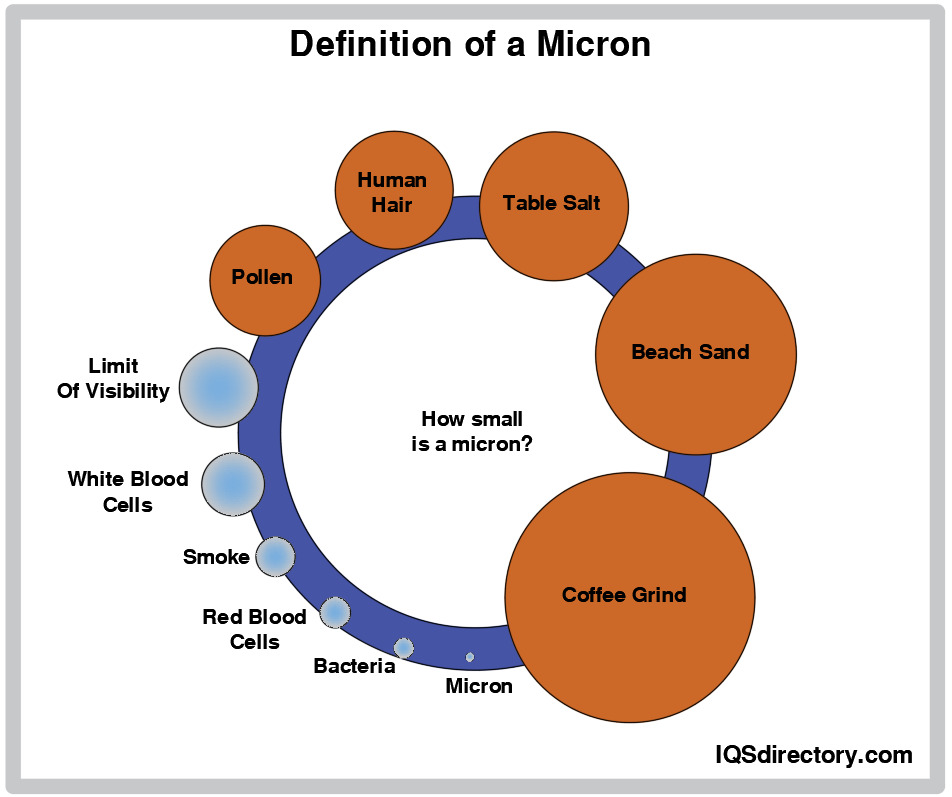

The particles measured in a clean room are far smaller and more minute than the types of pollen, dust, and dirt that can be seen with the naked eye. Clean room particles are measured in micrometers, or one-thousandth of a millimeter, and referred to as a micron (µ).

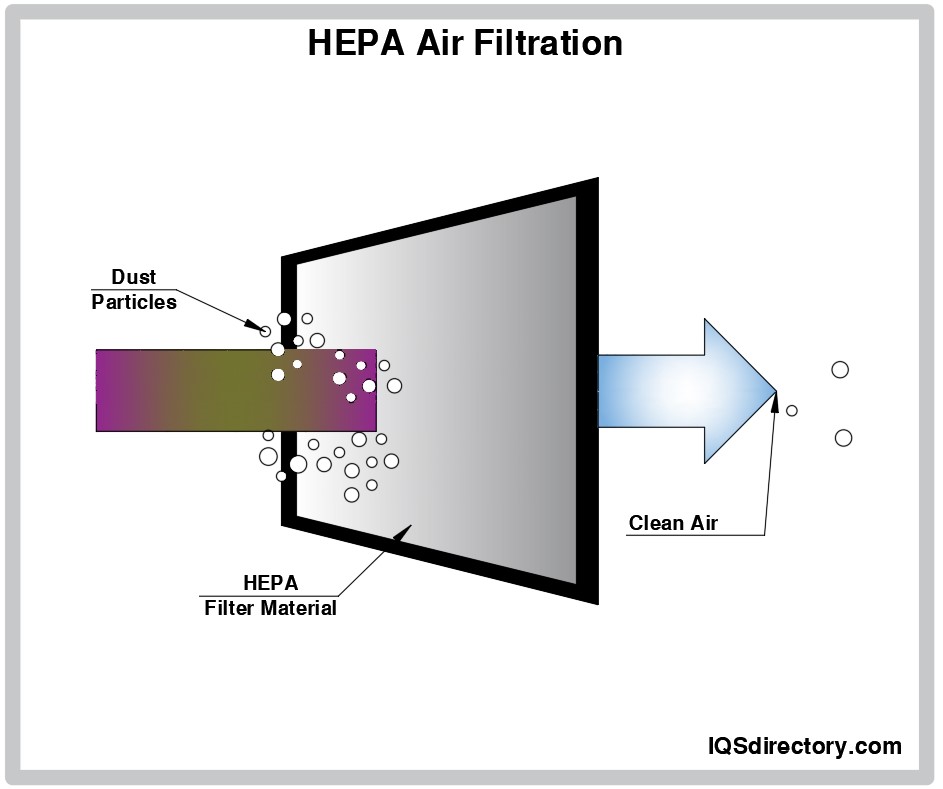

The US FED STD 209E standard system rates clean rooms based on the number of 0.5-micron particulates present per cubic foot in an enclosure. The particulate volume number decides the classification number assigned to a clean room. For example, Class 1 clean rooms have no more than one 0.5 micron particle per cubic foot. To achieve this low level of contamination, Class 1 clean room designs must have high-efficiency particulate air (HEPA) filters working in concert with other decontamination equipment.

As the class numbers increase, so does the acceptable level of particulate presence. For example, Class 10000 clean rooms contain no more than 10,000 0.5 micron sized particles per cubic foot. By comparison, the normal unfiltered air we breathe would be Class 1,000,000.

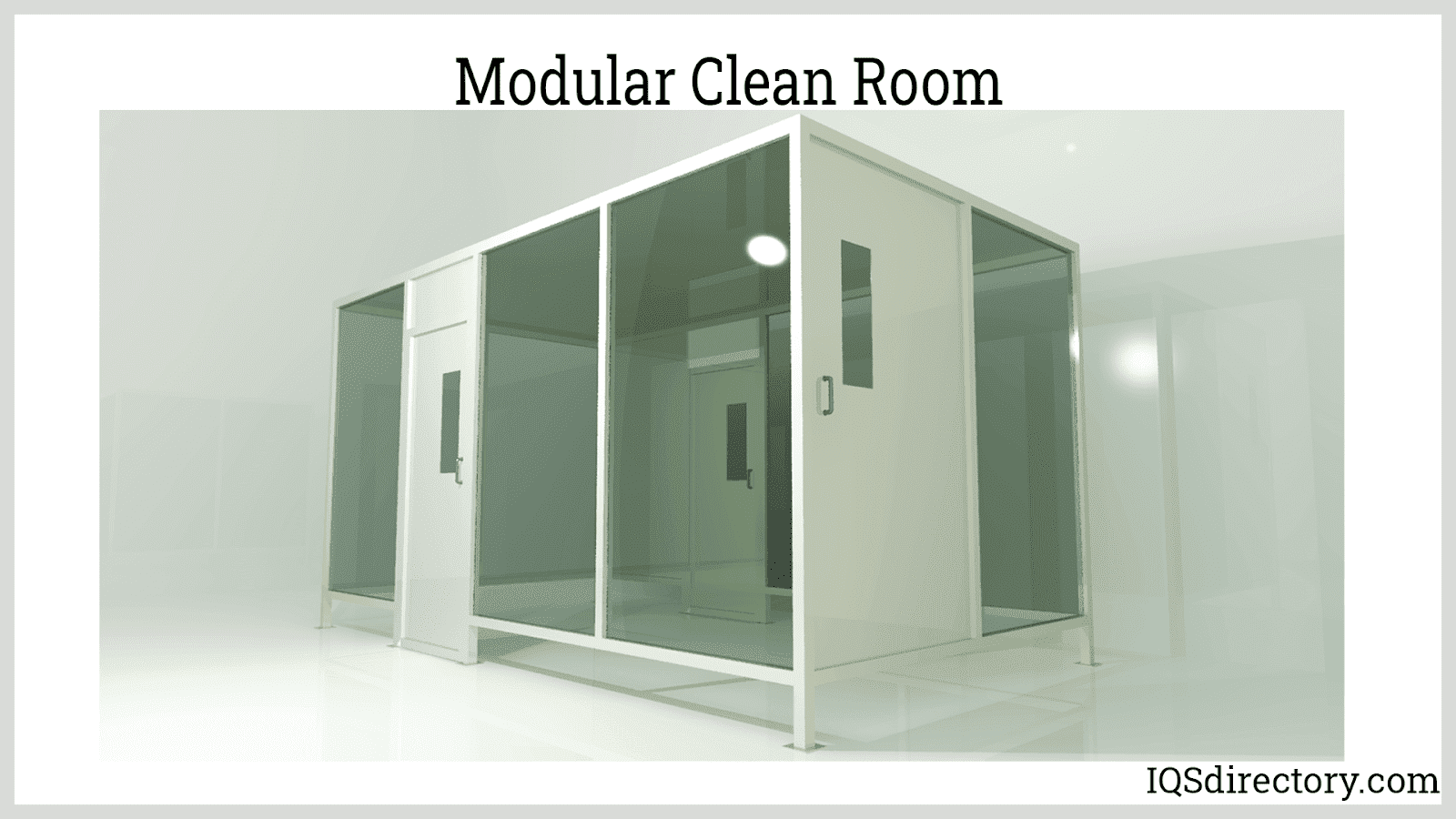

The lower the class number, the more likely the clean room has hard walls with a complex filtration and personnel decontamination system. Higher-class clean rooms, such as modular and portable ones, can be less permanent. They provide basic protection and can be moved easily and disassembled without difficulty.

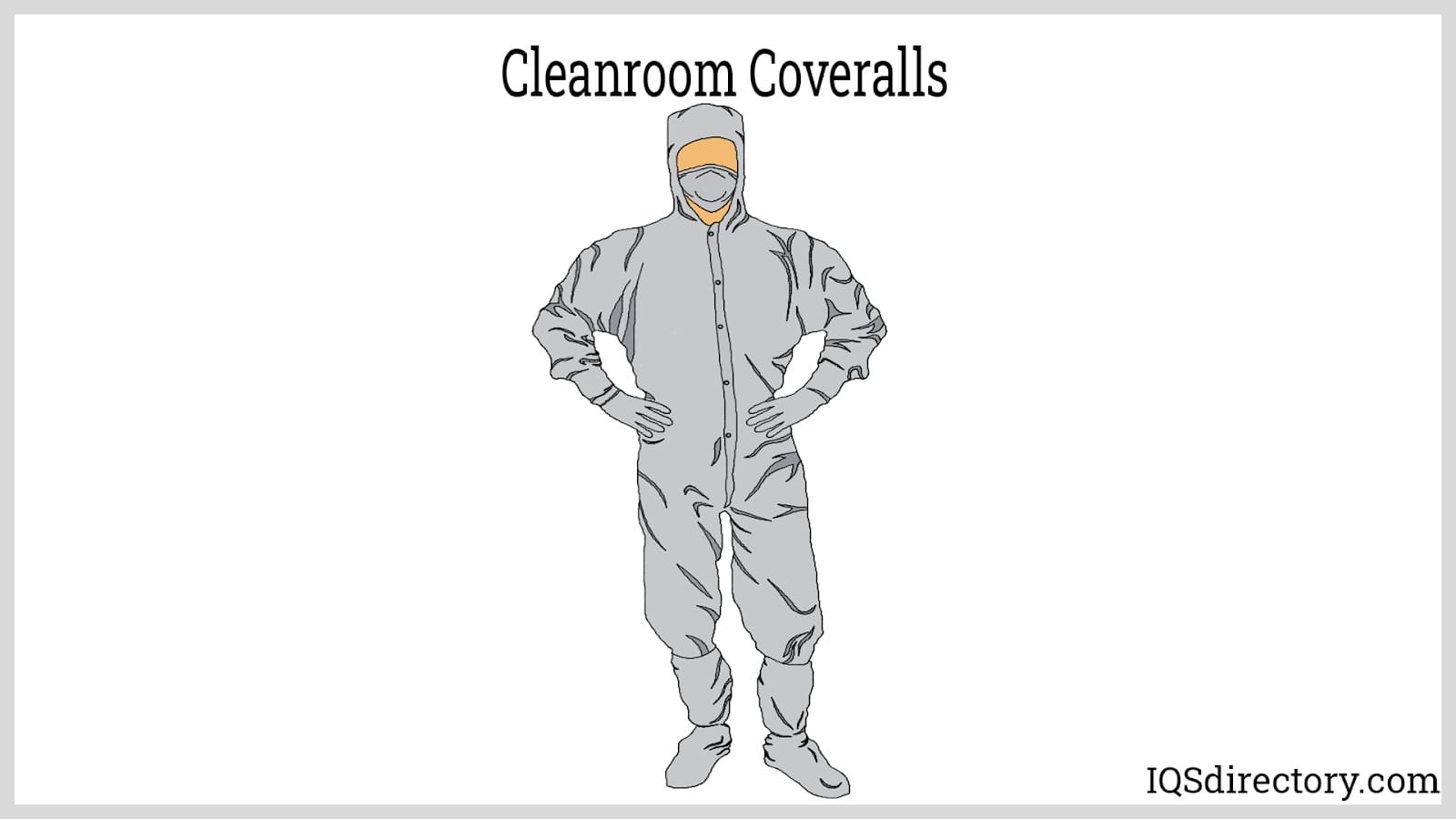

The design and structure of a clean room dictate the kinds of operations for which it can be used. This is also represented through the garments workers are permitted to wear. For example, class 1 clean rooms require employees to wear a bunny suit covering them from head to toe with a mask and synthetic gloves. In a Class 10000 clean rooms, workers can wear their own clothes but must have their hair, feet, hands, and faces covered. Additionally, class 1 clean rooms are small and limited to allow for better air supply control, while class 10000 clean rooms can be very large like classrooms.

Elements of a Clean Room

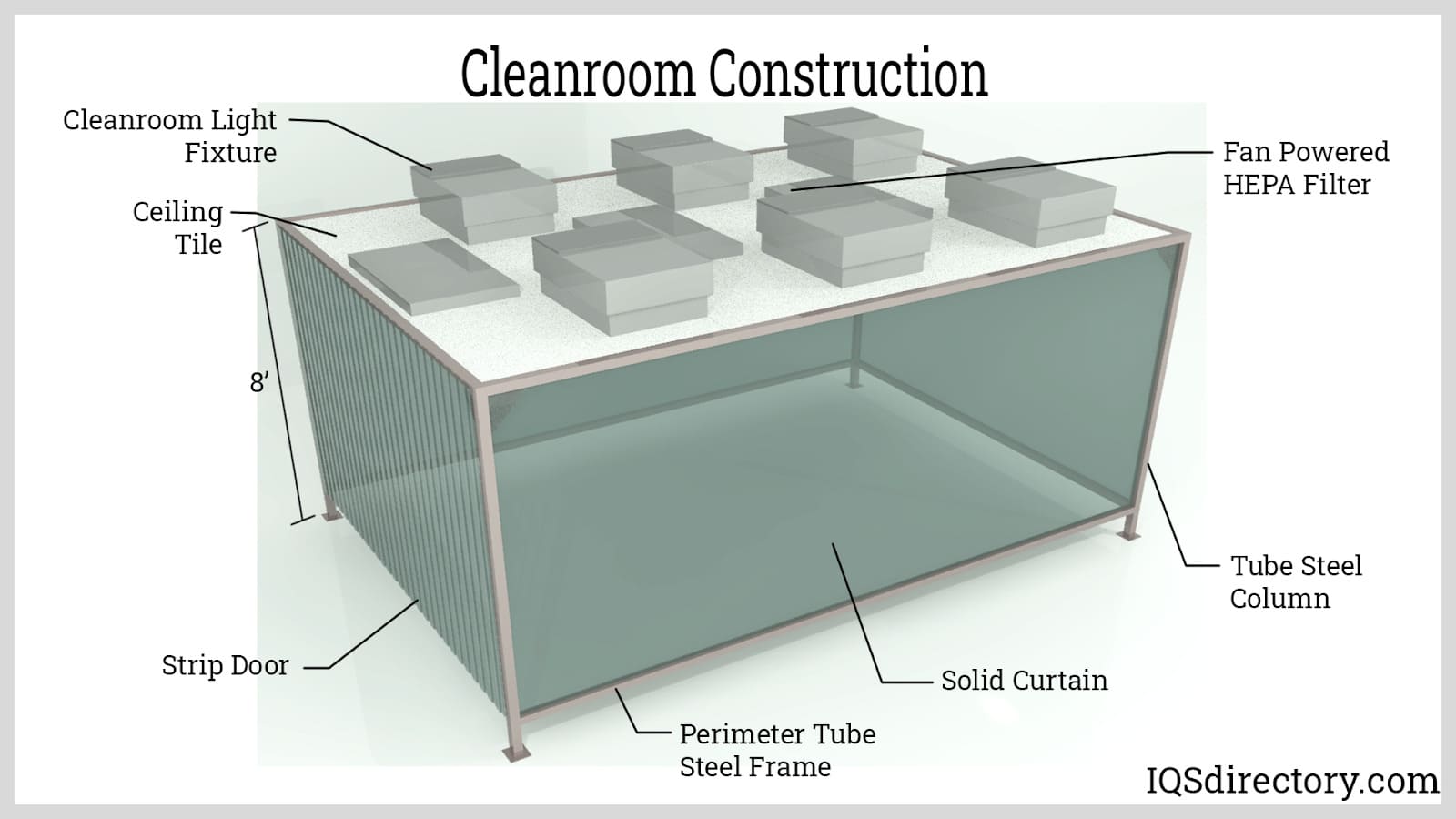

Three basic principles are considered when planning and designing a clean room. The first of those considerations is the quality of the air, which is the determining factor regarding a clean room's classification. Next is the size and number of surfaces of a clean room and the type of equipment used. The final component, and the one that supplies the most contamination, is the number of workers.

Air Filtration

The key element when defining a clean room is its quality of air. Controlling fresh air flow is simple since it involves passing a stream of air through a high-efficiency particulate air (HEPA) filtration system. The challenge is how to maintain that system without the clean room being contaminated. This aspect of the design process is the key to a high-performance clean room.

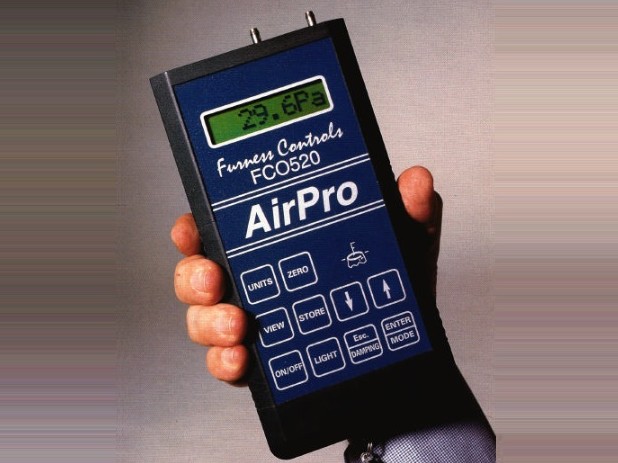

Each classification of clean rooms measures the air change rate (ACR), determined by how quickly the air in a clean room is replaced by clean filtered air. The ACR is the number of air changes per hour, with lower-class clean rooms having an ACR measured in changes per second. Additionally, the speed of the change is measured in feet per minute.

Knowing what atmosphere the industry requires is necessary when planning a clean room. Particle size and the number of particles in a cubic foot or meter must be carefully assessed regarding the product being tested or fabricated.

Clean Room Structure

Once the air filtration and cleanliness have been established, the next step is to design the walls, ceiling, floor, vents, and entryways for a clean room. Wall panels are made of resilient materials that are tightly secured. Ceilings have a metal hanging grid where tiles are securely placed. Finally, vents can be located on the floor or walls for easy airflow.

Personnel

The final element in clean room planning is the people who will work in it. Air control, clean walls and ceilings, and the seal of a clean room are static and seldom change. However, the personnel is constantly changing and carries a wide range of contaminants and bacteria, which must be monitored and controlled through body coverings, masks, and decontamination doors and pass thrus. The classification of a clean room determines the type of hygiene clean room staff must follow.

Selecting the Right Clean Room Design Company

For the most productive outcome when purchasing a clean room design from a clean room design company, it is important to compare several businesses using our directory of clean room design companies. Each clean room design company has a business profile page that highlights their areas of expertise and capabilities, along with a contact form to directly communicate with them for more information or to request a quote. Review each clean room design business using our patented website previewer to get a better understanding of what each company specializes in. Then, use our simple RFQ form to contact multiple clean room design businesses with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services