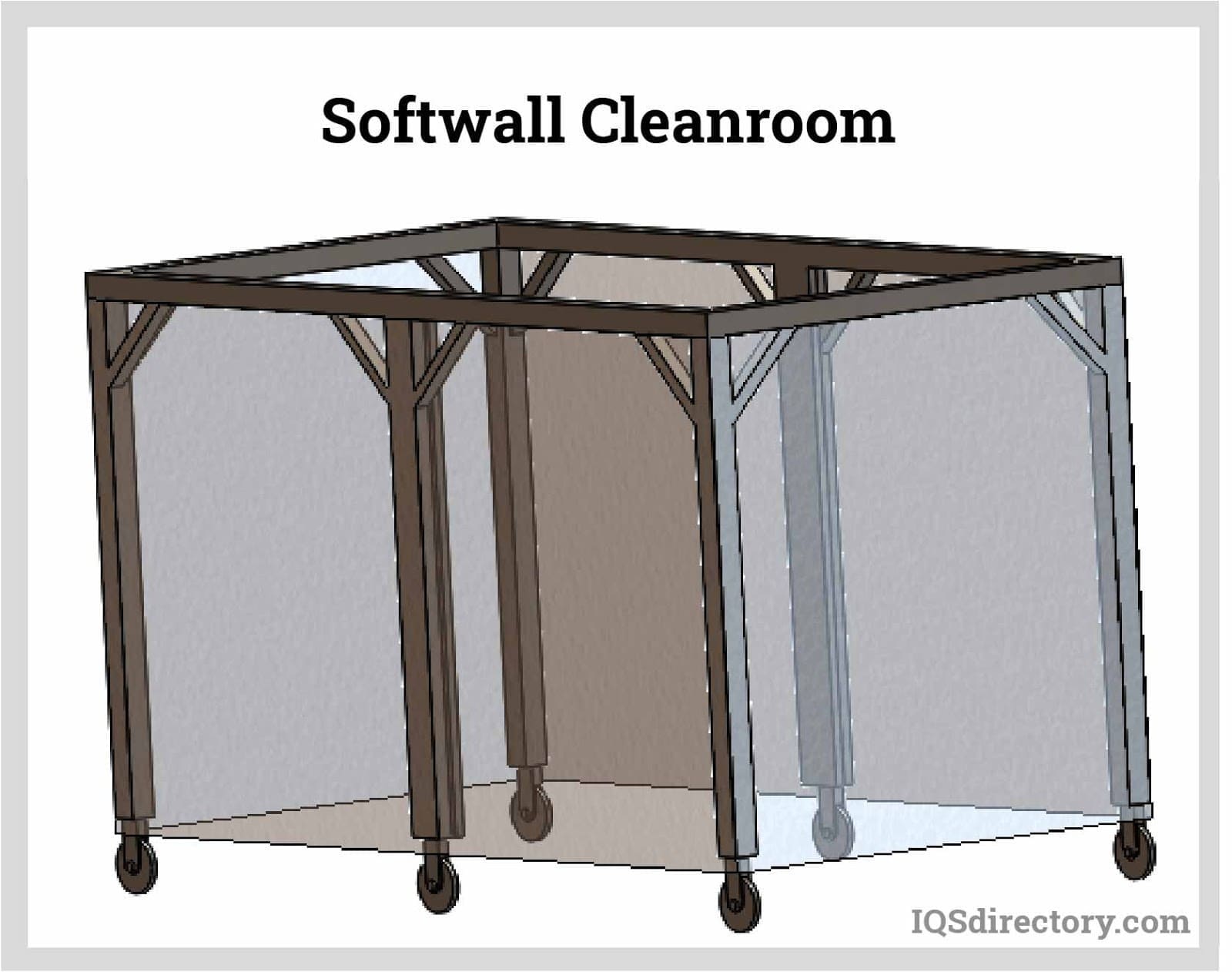

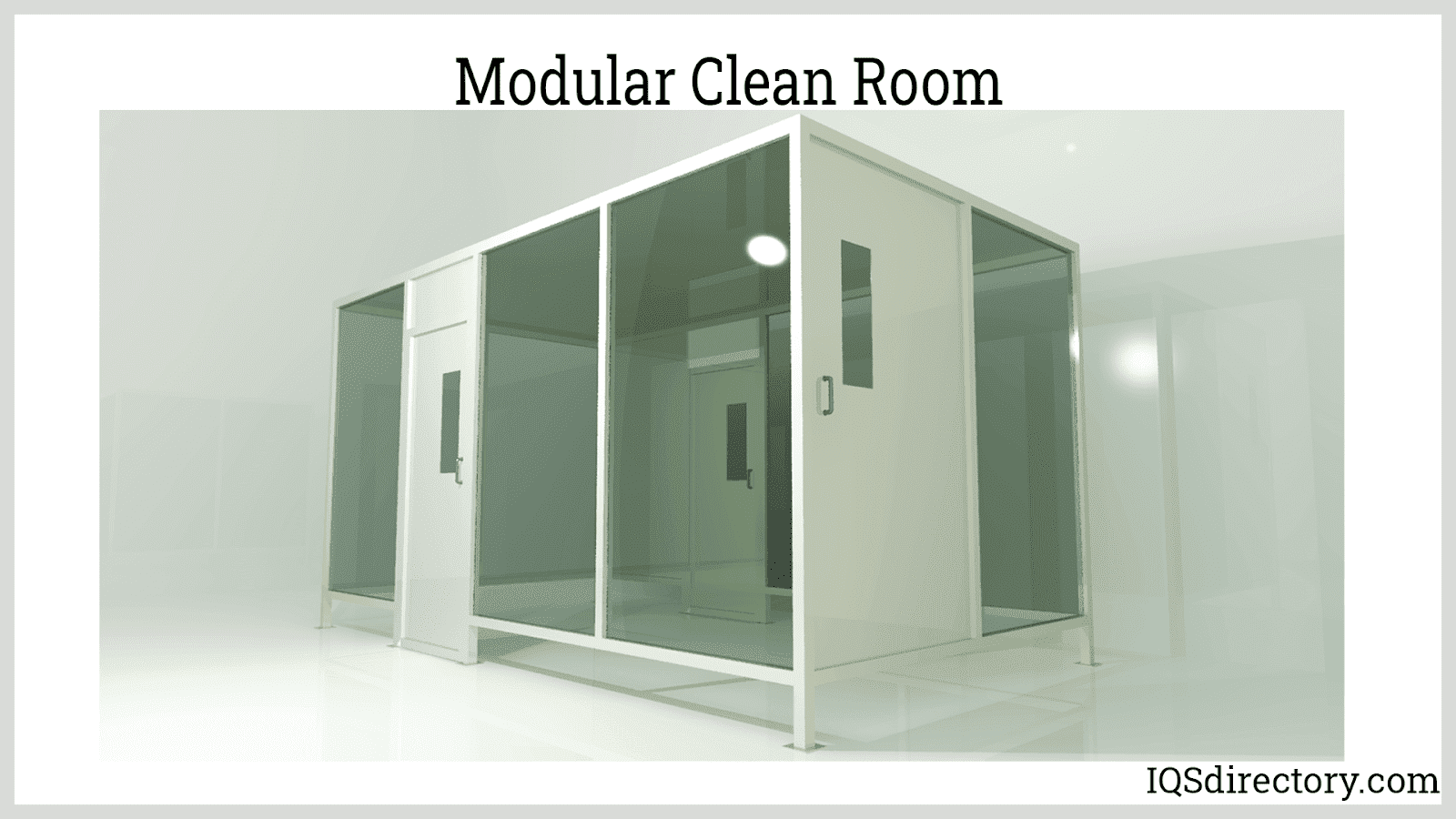

Softwall clean rooms are economical and flexible clean rooms that can be temporarily placed to meet production conditions that require an uncontaminated space. They have a metal frame with clear panel walls and high-efficiency particulate air (HEPA) filters to meet clean room requirements. Read More…

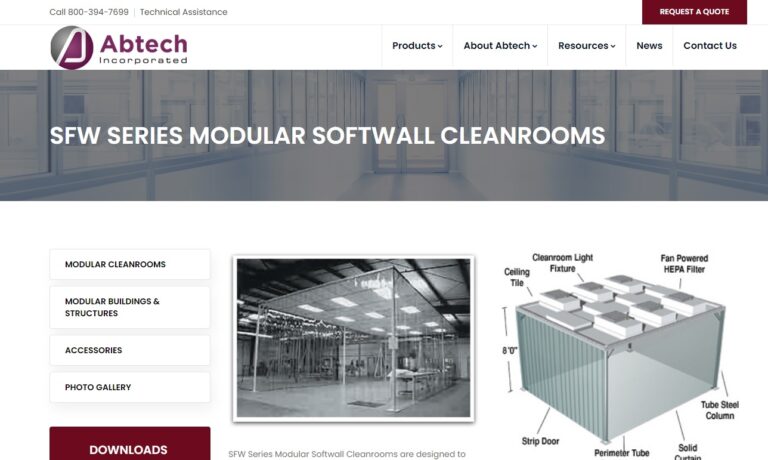

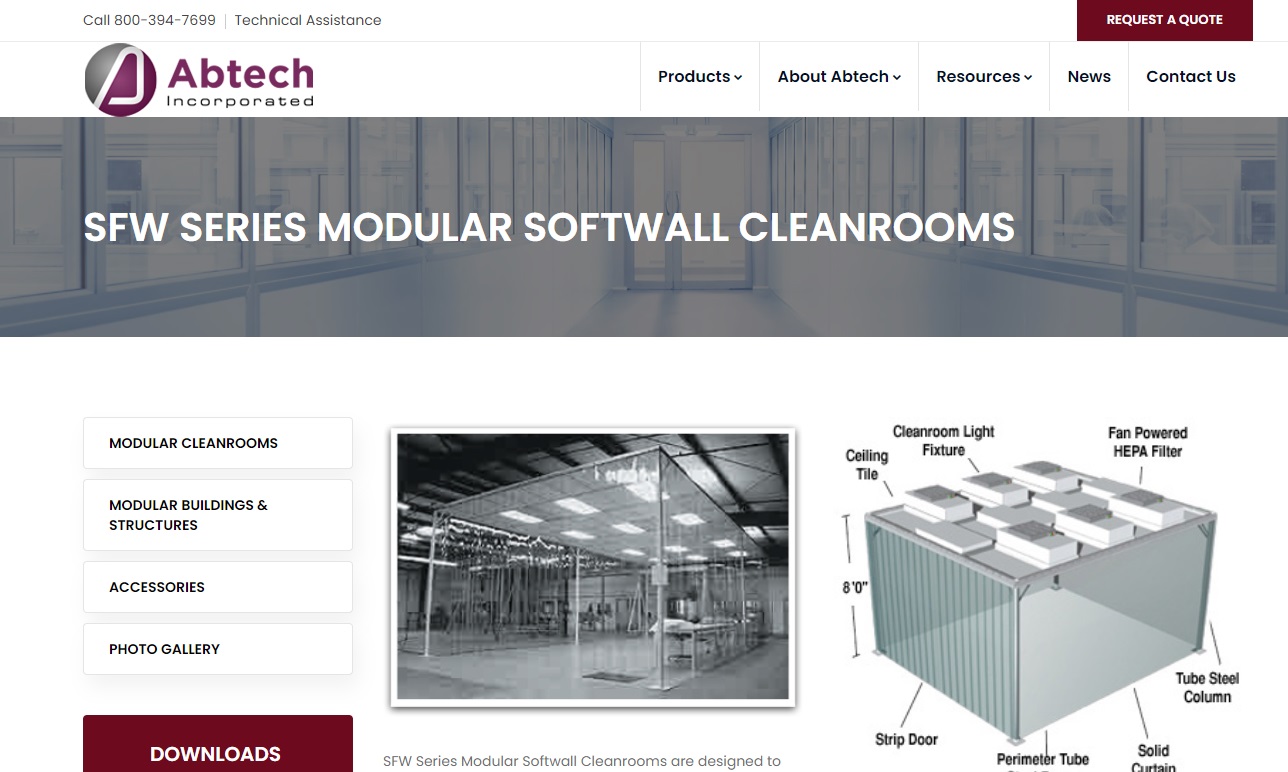

As a manufacturer of clean rooms, including inplant modular offices, exterior steel buildings, guard buildings, fork liftable and crane liftable buildings, multi-level buildings and mezzanines, Abtech offers turnkey installations or packages for install by end user. Our modular structures are constructed of steel, are free-standing & manufactured under strict quality control methods.

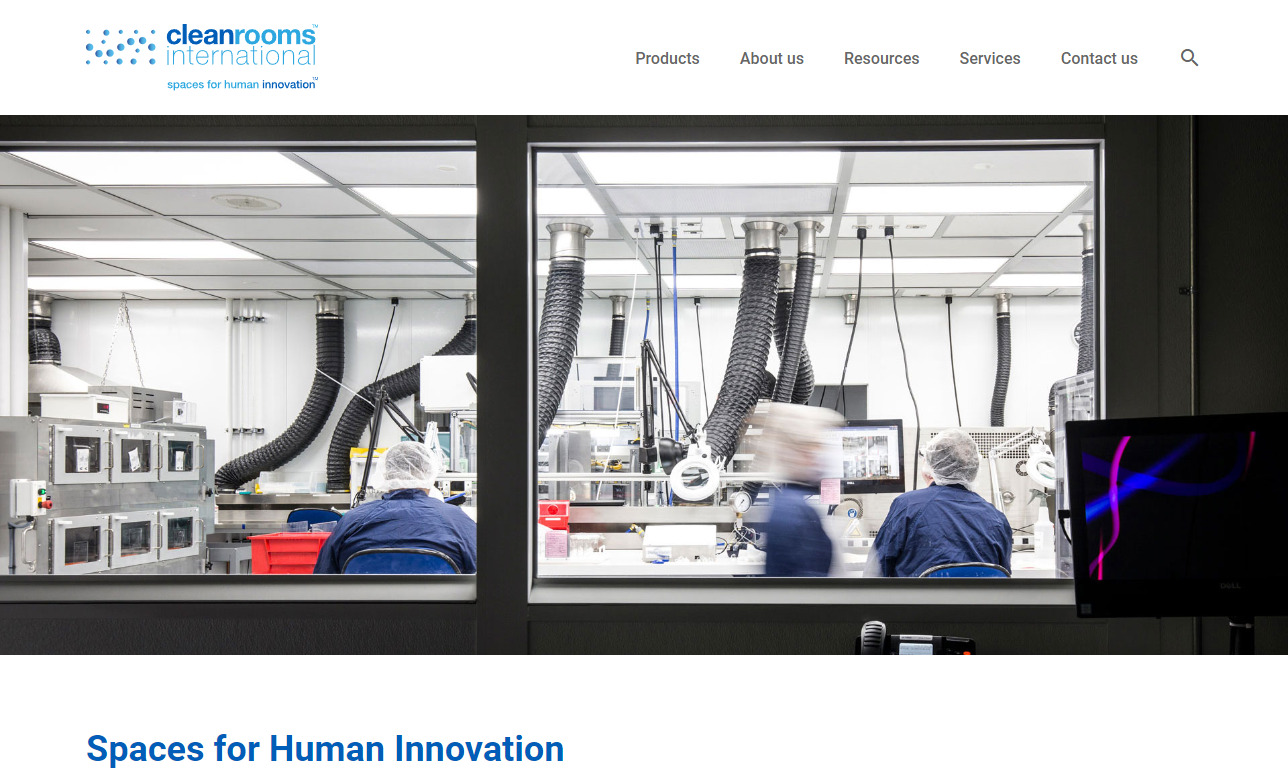

For the very best of clean rooms, look no further than Clean Rooms International! We can provide the ultimate in quality, customer service, durability, and unique designs just for you!

Cleanrooms By United is the industry’s premier manufacturer of modular clean room systems. We design, manufacture and install our clean rooms to meet our customers’ unique requirements. The custom, flexible, modular construction of our cleanrooms makes them easy to expand, reconfigure, or relocate as your cleanroom needs evolve.

Atmos-Tech Industries is a designer and manufacturer of cleanrooms and equipment for industries, including health care, pharmaceutical aerospace and automotive.

Our design staff is qualified with over 30 years of clean room experience. Our clean rooms are made from the highest quality materials and use a modular design that can be modified to suit any needs.

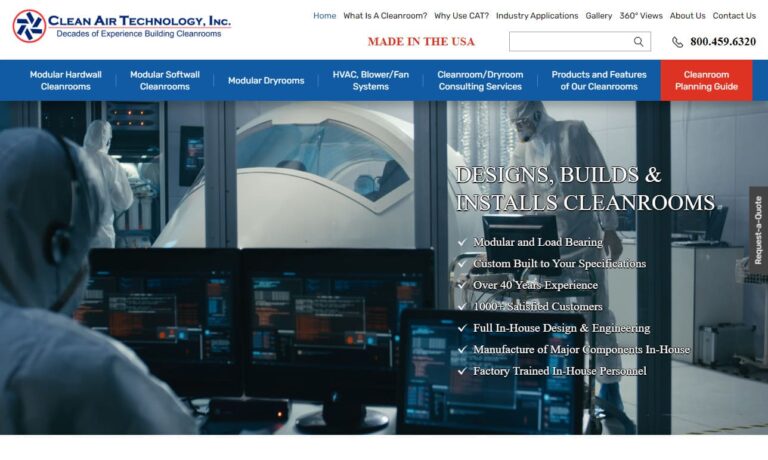

Our complete line of clean rooms will meet your needs. We are the experts of the clean room industry and our engineers can work with you to determine which clean room models work best for your business. We offer a variety of softwall, bio-clean, hardwall, and micro-clean options, all of which are manufactured with the highest standards. You will not be upset with our products. Contact us for more ...

Bayside Interiors is able to provide the design, engineering and construction of clean rooms. Bayside Interiors Inc. has been around since 1984. We also specialize in the construction of strut framing systems and facility support systems.

BASX Solutions has been designing and manufacturing truly modular cleanrooms since 1984. These are durable, scaleable, portable cleanrooms and are available in both softwall and hardwall designs. Our products meet the highest industry levels, from Class 100 to 100,000. Call for a free quick quote.

Since 1976, we at Mitchell Technical Sales have been dedicated to delivering excellence in quality cleanroom design, manufacturing, installation, certification, and maintenance. Our journey has been marked by innovation and expertise, ensuring that every project we undertake reflects our commitment to precision and cutting-edge solutions.

Welcome to Cleanrooms USA, where we pride ourselves on delivering unparalleled expertise and innovative solutions in the realm of cleanroom technology. At Cleanrooms USA, we are dedicated to providing cutting-edge cleanroom environments that meet the stringent requirements of industries ranging from pharmaceuticals and biotechnology to electronics and aerospace.

More Softwall Cleanroom Manufacturers

Softwall clean rooms are easy to install and can be adjusted to fit the needs of any fabrication conditions.

Softwall clean room sizes range from 4 feet by 4 feet (1.2 x 1.2 m) to 24 feet by 36 feet (7.3 x 11 m). A popular feature of softwall clean rooms is their ability to be adjusted and expanded by adding extra wall framing and ceilings. Softwall clean rooms are the first choice for many industries since installing permanent or modular clean rooms is more expensive and unnecessary.

Softwall clean rooms are easy to install and portable, making them more economical than hard wall clean rooms. They are helpful for smaller-scale operations that do not require constant access to a controlled working environment. When combined with other control measures, such as protective clothing for workers, HEPA air filters, and double doors, softwall clean rooms can achieve sufficiently high levels of decontamination.

Clean Room Classification

Clean rooms are subject to governmental regulatory standards as well as international standards from the ISO. The United States government and the ISO have different standards that clean room manufacturers observe.

Federal Standard 209E (US FED STD 209E) for clean rooms is based on the number of 0.5 micrometer-sized particles per cubic foot of air in a clean room. Class 1 clean rooms, for example, have no more than one 0.5 micrometer-sized particle per cubic foot in their atmosphere.

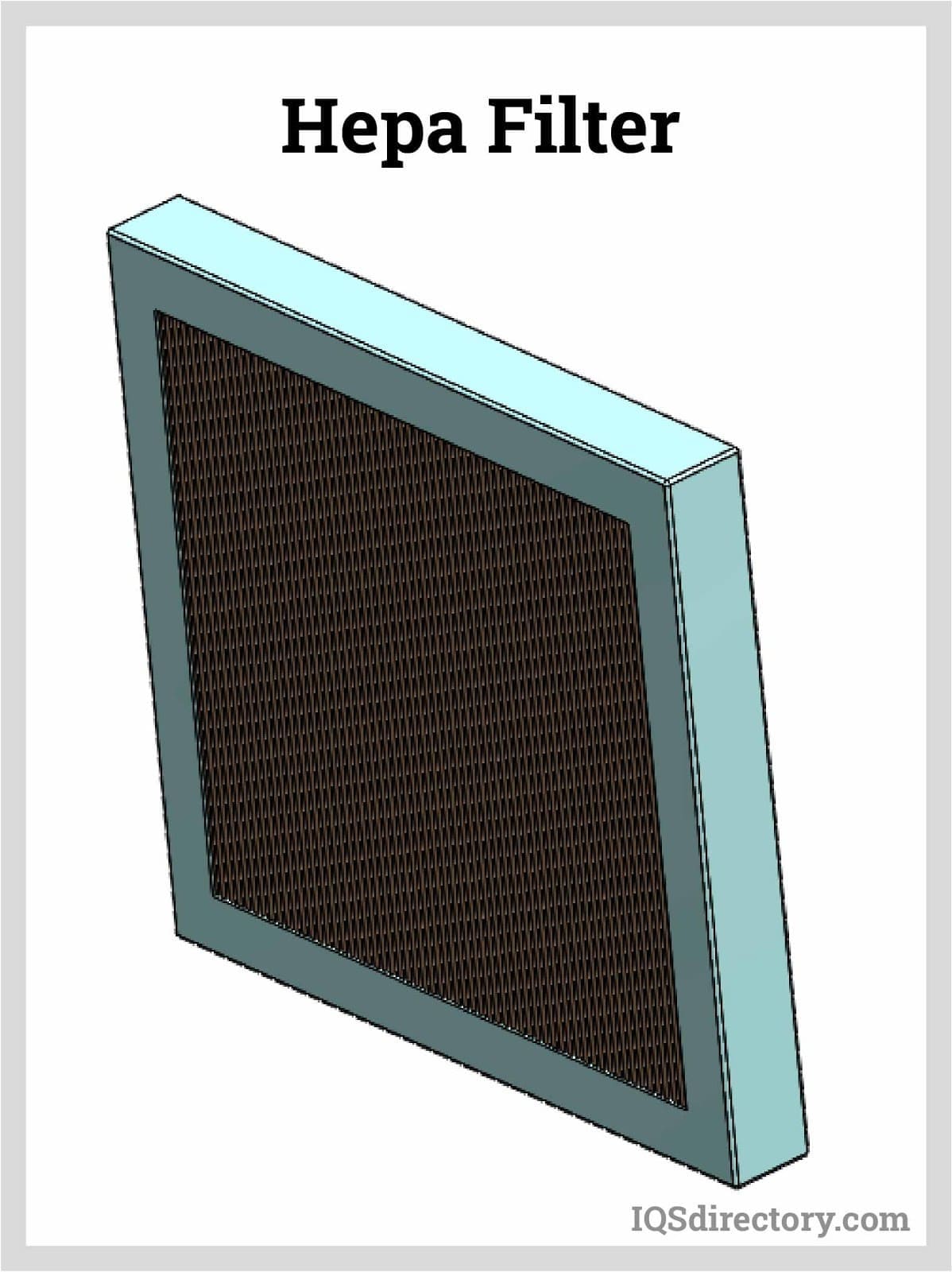

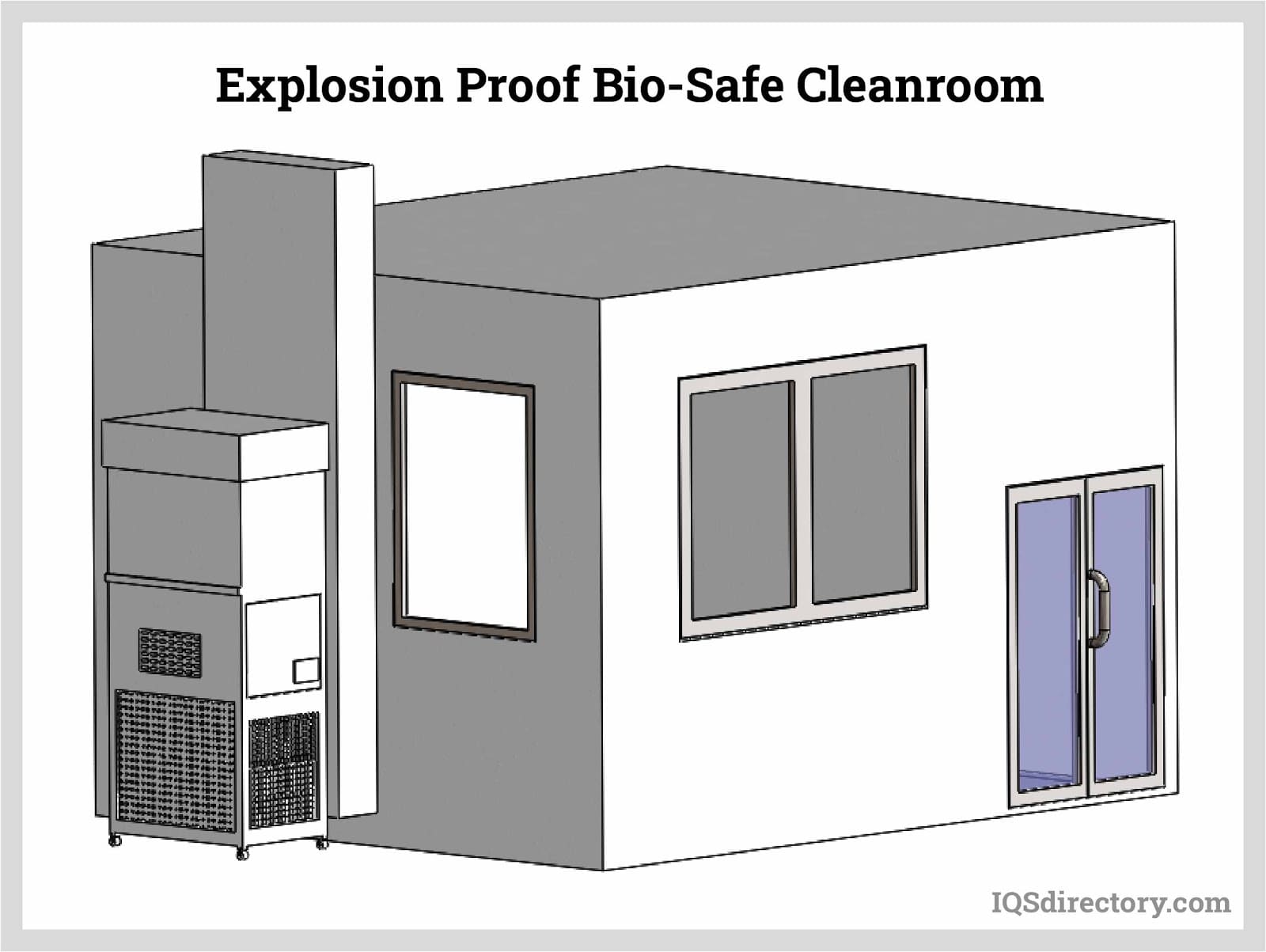

This extremely low level of contamination is maintained by a complex system of HEPA filters, working in concert with personnel decontamination systems, sterilization chemicals, and other procedures. Softwall clean rooms are generally incapable of reaching such a high level of decontamination. Permanent, hard-walled enclosures with double doors and decontamination air jets are better able to generate Class 1 conditions.

Such an extreme level of decontamination is not necessary for many sensitive applications. Classes 100, 1,000, and even 10,000, whose classification numbers correspond with the volume of particles per cubic foot of air, are suitable for many high-tech operations, and softwall clean rooms can meet those decontamination levels.

Softwall Clean Room Design

There are several factors to consider when designing any clean room capable of meeting the exacting standards of the ISO and Federal Standard 209. The main factor that is first addressed is air quality, which varies depending on particulate content. ISO 8 or 10000 clean rooms can be entered without needing a sealed door or airlock, a classification that softwall clean rooms meet.

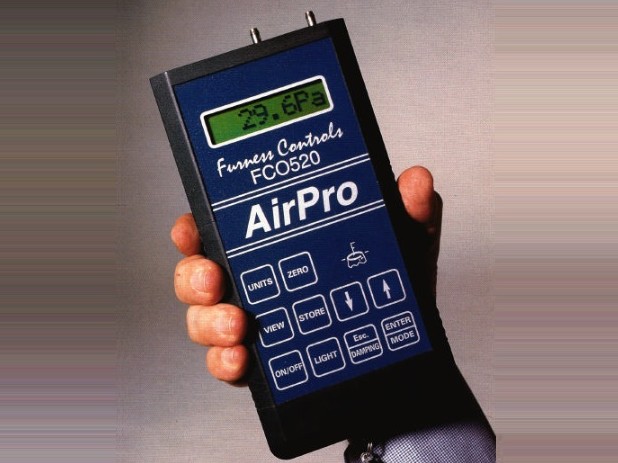

Air Treatment System

The quality of the air treatment system is the linchpin for clean rooms and is dependent on the use of HEPA filters that remove 99.99% of contaminants. For softwall clean rooms, the air treatment system is located in the ceiling, with air being vented under the softwalls. The air change rate (ACR) determines an air treatment system's capabilities, which refers to how often the air in the clean room is replaced with fresh, clean air. For an ISO 8 class clean room, the ACR is 5 to 48 times per hour.

Softwall Clean Room Walls

The walls of softwall clean rooms are made of thick clear vinyl that is flame-retardant and outgassing. They are lightweight and easy to install and clean. Softwall vinyl is made of 40 mil vinyl and is hung such that they overlap with doors of 80 mil vinyl. The strength and thickness of the vinyl make the walls tear-resistant. They are attached using a grip track mounting frame.

Support Frame

The frame of softwall clean rooms is made of powder-coated steel or aluminum for uprights, cross beams, and ceiling frames. An essential aspect of the support frame is its ability to support the many parts of the air treatment system. Since support frames come in several sizes and shapes, they can be customized to fit a customer's requirements.

Ceiling Grid

Softwall cleanroom ceilings are a grid system cross-connected by lightweight metal tubing or rods. Some softwall clean room systems have hanging ceils connected with turnbuckles for extra stability and support; however, this type of system limits the mobility and flexibility of a softwall clean room.

Clearance for a softwall clean room must be carefully measured when installed in a building since clean rooms require at least a two-inch clearance from a building's ceiling. High-quality HEPA filtration systems are normally 16 inches (40.6 cm) for a softwall clean room, which limits the height of the clean room in a normal building to between seven to ten feet (2.1 to 3 m).

Industries That Use Softwall Clean Rooms

Softwall clean rooms have become the norm for industries that require an uncontaminated environment. Due to their low cost, flexibility, easy assembly, and low maintenance, they are ideal for providing atmosphere-controlled conditions. Although they may seem the perfect choice for small industries, they are also viable for large manufacturing operations that require a temporary clean environment.

Plastics Industry

The flexibility of softwall clean rooms makes it possible for plastic manufacturers to quickly shift their focus from one type of material to another. Softwall curtains enable a workspace to expand to meet a project's needs.

The small footprint of softwall clean rooms allows them to fit into any workspace regardless of its size and be streamlined to meet the needs of an application.

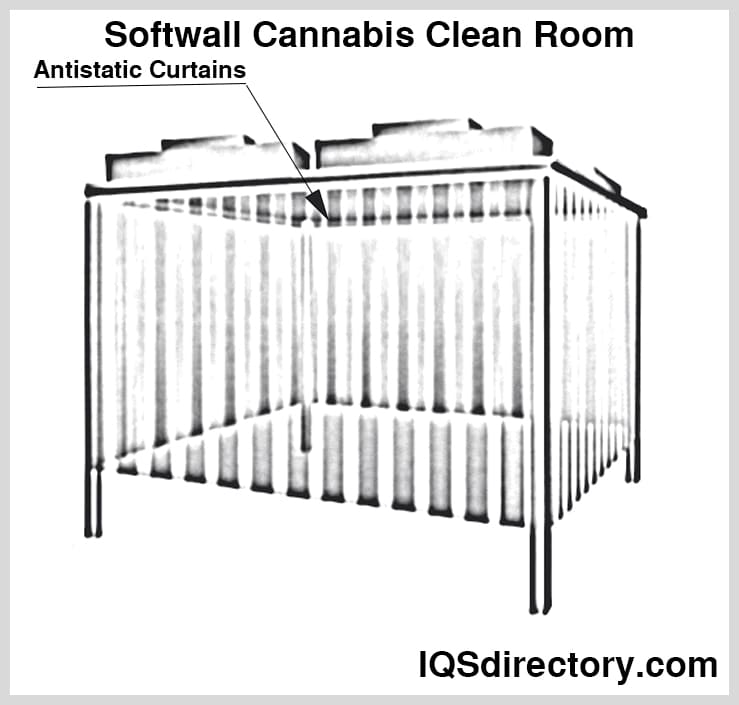

Cannabis Production

A central aspect of the production of cannabis is the use of softwall clean rooms that provide an environment for the manufacture of medical-grade cannabis. The Food and Drug Administration (FDA) stipulates that softwall clean rooms for cannabis production must have ISO 5 or ISO 7 classifications to ensure that the manufacturing process meets quality and safety requirements.

Food and Beverage

The regulations for food and beverage production are very rigorous and demanding. Softwall clean rooms are widely used in food production to help minimize the exposure of food products to contaminants such as germs, bacteria, and fungi. The FDA demands to ensure safe and clean production of food. The nature of softwall clean rooms helps to increase the shelf life of food by avoiding exposure to detrimental agents since the filtration system removes allergens such as gluten and lactose.

Semiconductor Industry Uses

The many processes of semiconductor manufacturing require softwall clean rooms with ISO 5 or ISO 7 classifications to meet the particulate count needed for a clean working space. Such conditions require a flexible space for assembly, testing, and fabricating components. Softwall clean rooms are ideal for the conditions since they can be extended and spread to meet the needs of any workspace.

As part of the special conditions for semiconductor construction, special dark curtain areas are necessary for UV inspections. The flexibility of softwall clean rooms makes it possible to turn any space into a UV examining area with the addition of dark curtains.

Selecting the Right Softwall Clean Room Company

For the most productive outcome when purchasing a softwall clean room from a softwall clean room manufacturer, it is important to compare several businesses using our directory of softwall clean room companies. Each softwall clean wall manufacturer has a business profile page highlighting their areas of expertise and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each softwall clean room business website using our patented website previewer for an understanding of what each company specializes in. Then, use our simple RFQ form to contact multiple softwall clean room businesses with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services