Cleanroom classifications are a method used to determine what types of manufacturing, research, tests, and procedures that can be completed in a cleanroom. The two types of cleanroom classification are United States Federal Standard 209 (FED-STD-209) and the International Organization of Standardization (ISO). The two systems have the same intent using different numbering systems. Read More…

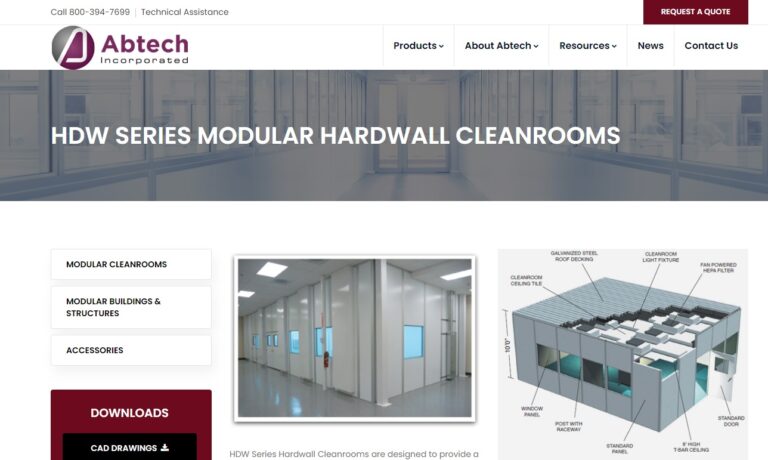

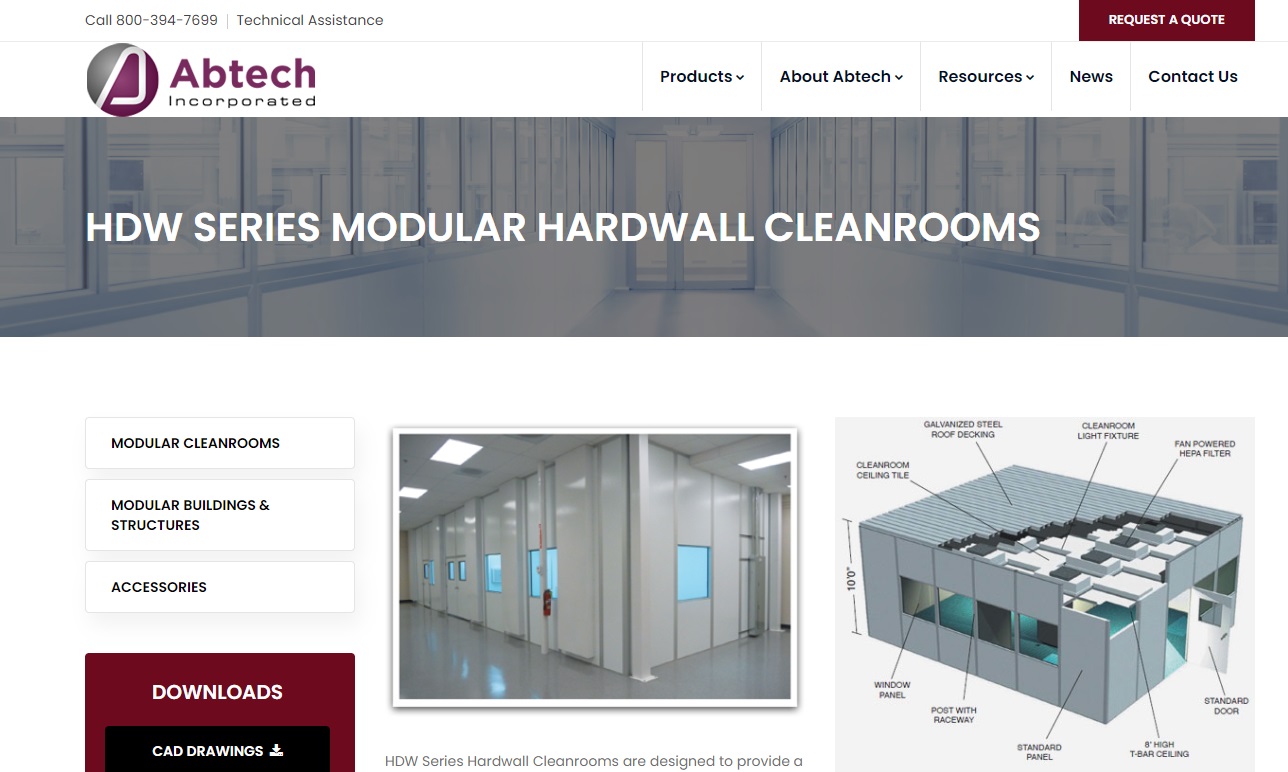

As a manufacturer of clean rooms, including inplant modular offices, exterior steel buildings, guard buildings, fork liftable and crane liftable buildings, multi-level buildings and mezzanines, Abtech offers turnkey installations or packages for install by end user. Our modular structures are constructed of steel, are free-standing & manufactured under strict quality control methods.

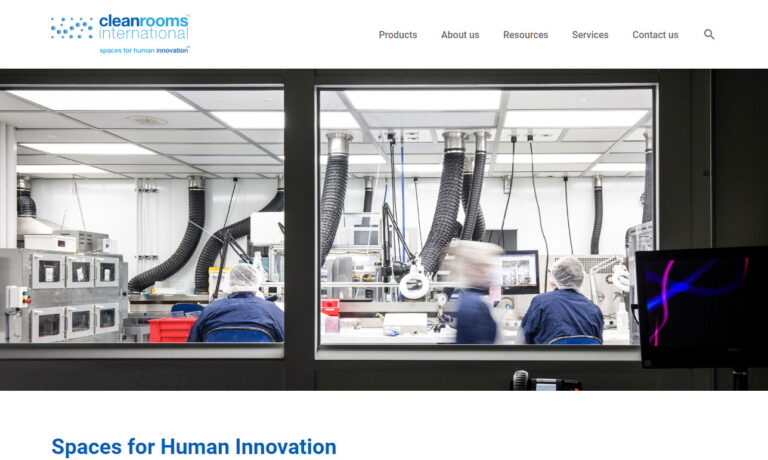

For the very best of clean rooms, look no further than Clean Rooms International! We can provide the ultimate in quality, customer service, durability, and unique designs just for you!

Cleanrooms By United is the industry’s premier manufacturer of modular clean room systems. We design, manufacture and install our clean rooms to meet our customers’ unique requirements. The custom, flexible, modular construction of our cleanrooms makes them easy to expand, reconfigure, or relocate as your cleanroom needs evolve.

Atmos-Tech Industries is a designer and manufacturer of cleanrooms and equipment for industries, including health care, pharmaceutical aerospace and automotive.

Our design staff is qualified with over 30 years of clean room experience. Our clean rooms are made from the highest quality materials and use a modular design that can be modified to suit any needs.

Our complete line of clean rooms will meet your needs. We are the experts of the clean room industry and our engineers can work with you to determine which clean room models work best for your business. We offer a variety of softwall, bio-clean, hardwall, and micro-clean options, all of which are manufactured with the highest standards. You will not be upset with our products. Contact us for more ...

Bayside Interiors is able to provide the design, engineering and construction of clean rooms. Bayside Interiors Inc. has been around since 1984. We also specialize in the construction of strut framing systems and facility support systems.

BASX Solutions has been designing and manufacturing truly modular cleanrooms since 1984. These are durable, scaleable, portable cleanrooms and are available in both softwall and hardwall designs. Our products meet the highest industry levels, from Class 100 to 100,000. Call for a free quick quote.

Since 1976, we at Mitchell Technical Sales have been dedicated to delivering excellence in quality cleanroom design, manufacturing, installation, certification, and maintenance. Our journey has been marked by innovation and expertise, ensuring that every project we undertake reflects our commitment to precision and cutting-edge solutions.

Welcome to Cleanrooms USA, where we pride ourselves on delivering unparalleled expertise and innovative solutions in the realm of cleanroom technology. At Cleanrooms USA, we are dedicated to providing cutting-edge cleanroom environments that meet the stringent requirements of industries ranging from pharmaceuticals and biotechnology to electronics and aerospace.

More Class 100 Clean Room Manufacturers

The Fed-Std-209 standard numbering system begins at 1 and goes to 10, 100, and 1,000 up to 100,000 with 1 being the most secure type of cleanroom and 100,000 being the least clean. The ISO numbering system begins at ISO 1 and progresses to ISO 8. The first level of the Fed-Std-209 system is equal to an ISO 3 rating.

The efficiency of a cleanroom is measured by the size of particles of dirt, dust, or pollen using a micron (µ) as the means of measurement, which is one millionth of a meter. For a class 100 cleanroom, particles must be equal to or less than 0.5 µ for every 100 cubic feet of the room.

Class 100 cleanrooms are the third most clean environment and are used for biotechnology, pharmaceuticals, and nanotechnologies. They are used for the manufacture of high purity chemicals and sensitive research.

Critical Components of Class 100 Cleanrooms

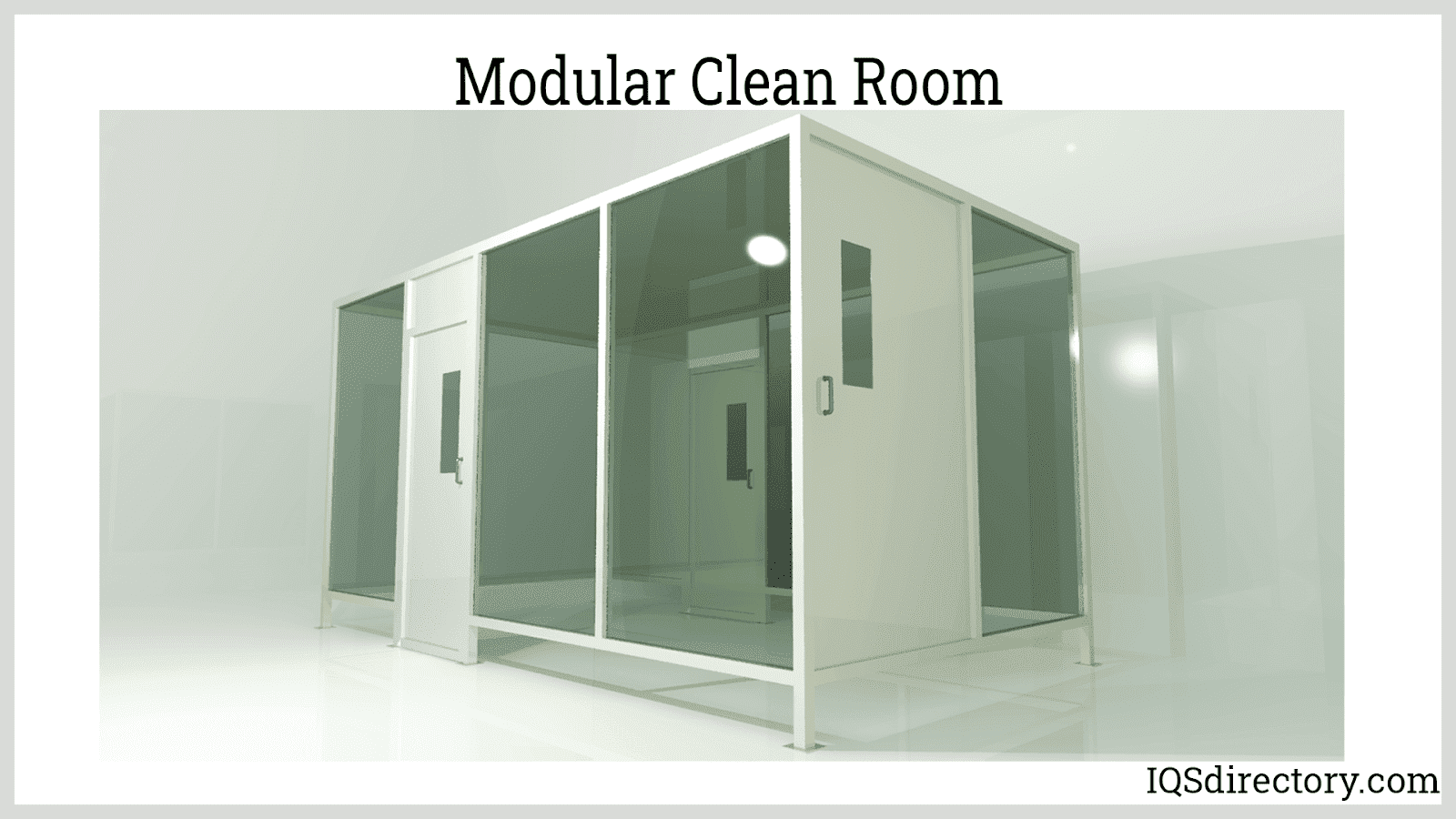

Each class of cleanroom has specifications that must be followed for a cleanroom to meet the required standards. Some of the critical areas are air flow design, walls, floor, ceiling, and ventilation. The various stipulations are the defining factors that make a cleanroom a cleanroom. Class 100 cleanrooms can have hard or soft walls and be portable or permanent with portable class 100 being the most common.

Airflow

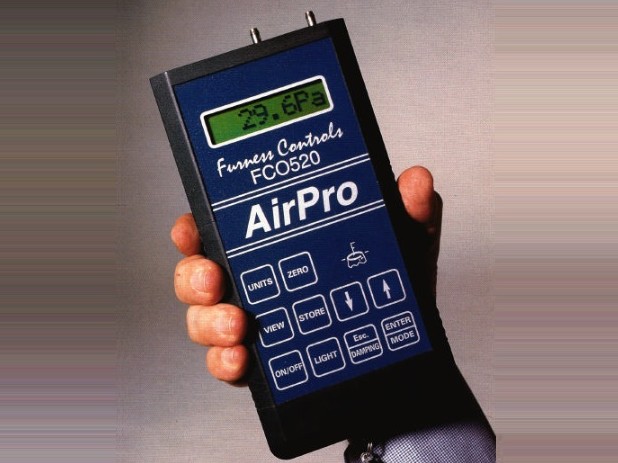

Class 100 cleanrooms must have filtration coverage of 60% to 70% with an air change rate of 300 per hour. The standard air flow rate for a class 100 clean room is 36 to 65 cubic feet per minute per square foot. Air flow can be recirculating or unidirectional.

For class 100 cleanrooms, unidirectional or laminar airflow is preferred with a ventilated raised floor. Air is supplied linearly from HEPA filters. The drawback to unidirectional airflow is its expense, which is more than other airflow systems.

As filtered air comes down into the room, it enters at a rate of 0.3 m/s up to 0.5 m/s and exits through the raised floor. This airflow process makes it possible for a cleanroom to meet the standards for a class 100 cleanroom or ISO 5 cleanroom.

The airflow system of a class 100 cleanroom is maintained at positive pressure that is higher than the air pressure outside the cleanroom, which forces the air inside the cleanroom to flow outside. This process prevents contaminated particulate matter from entering the cleanroom.

Walls

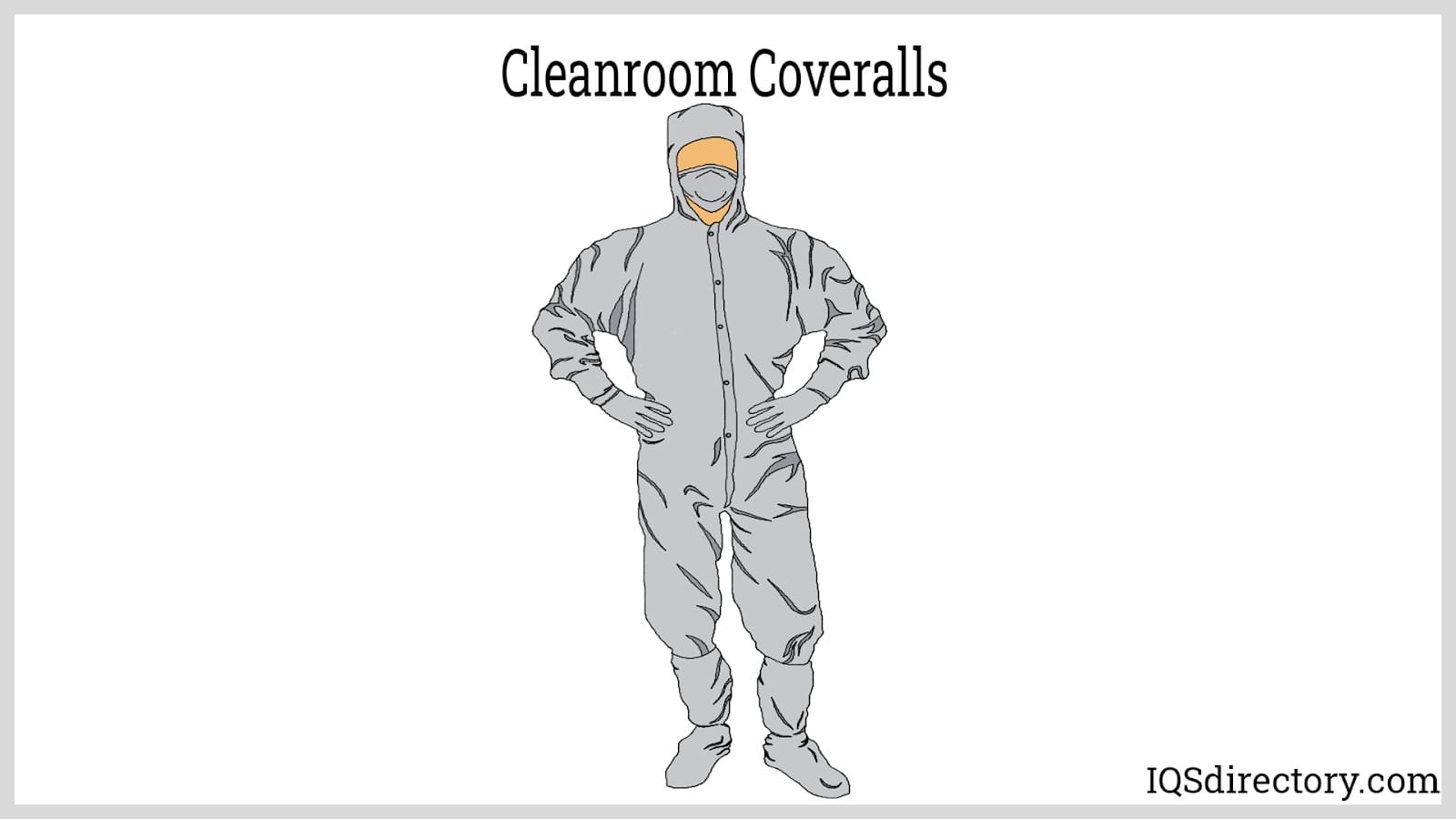

The three types of walls for class 100 cleanrooms are hard, soft, and rigid with hard walls being made of solid insulated material while soft walls are made of various types of strong durable polymers. The key difference between the walls is the types of materials from which they are made.

- Hard Walls – Solid hard walls are made of stainless steel, vinyl, plastic laminate, aluminum, or fiberglass. They are the most secure form of walls and the cleanest. Hardwall cleanrooms can meet any type of cleanroom classification.

- Soft Walls – Softwall cleanrooms have walls made of vinyl sheets with various types of finishes. They can easily meet the standards for a class 100 cleanroom.

- Rigid Walls – Rigid walls are a combination of soft and hard walls and are the most flexible of the wall materials. They have the hardness of hard walls with the visibility of soft walls. They are made from clear acrylic and meet the standards of a class 100 cleanroom.

Ventilation

The ventilation system of a cleanroom is highly complex but is the cleanroom's most critical aspect. It provides special treatment of cleanroom air and is designed for use in sealed, restricted, and uncontaminated rooms. Air is the transport method that contaminates use to pollute an environment. The ventilation system ensures that the negative particulates in the air are removed to maintain cleanroom standards.

Floor

The flooring of a cleanroom holds the structure together and supports all of the cleanroom activities. With class 100 cleanrooms, a raised floor with perforated grid panels is preferred for increased airflow as well as the reduction of conductivity and static electricity. Although perforated panels may be preferred, solid and grated panels can be used in their place.

High Efficiency Particulate Air (HEPA) Filters

The key to the efficiency of any cleanroom is the ability of the filtration system to remove particulate matter. HEPA filters are the first choice for all cleanrooms, which are capable of removing 99.9% of all particulate matter that has sizes of 0.3 µm³ using their unique design and multiple filters. They capture bacteria, spores, pollen, viruses, and other varieties of contaminates.

HEPA filters are placed in the ceiling of a class 100 cleanroom to provide unidirectional air flow. They have a low pressure drop that allows for maximum air flow. More advanced and higher efficiency filters are ultra-low particulate air (ULPA) filters that remove 0.12 µm particulate matter. ULPA filters may be necessary for a class 100 cleanroom depending on the ambient air outside the cleanroom.

Types of Class 100 Cleanrooms

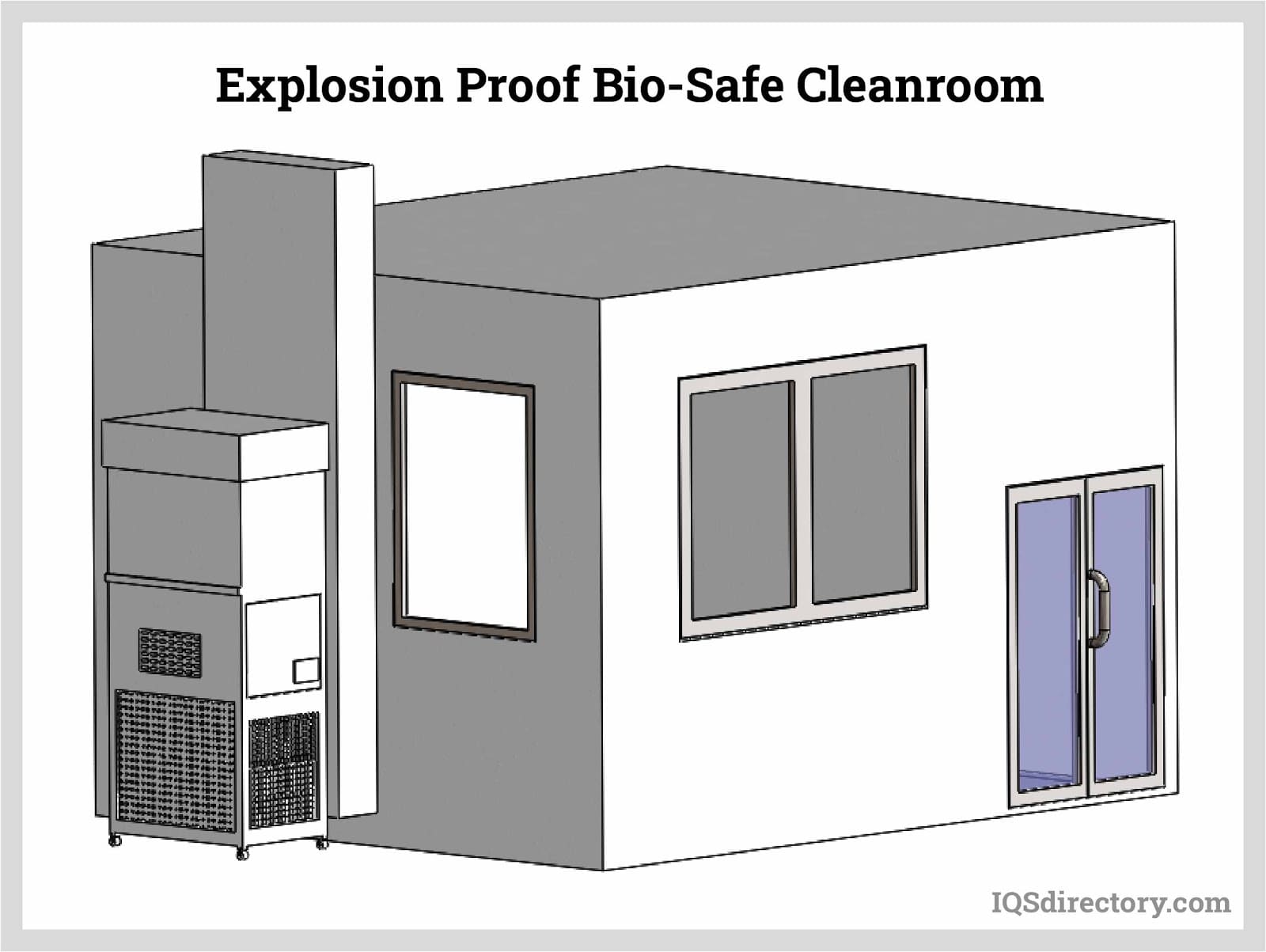

Class 100 cleanrooms come in a wide assortment of designs and configurations that change according to the manufacturer. Softwall and hardwall cleanrooms are the two basic types and the ones that are most commonly used. One particular version of a hardwall cleanroom is a prefabricated cleanroom that has hardwalls, is mobile, and can be set up quickly and easily.

Prefabricated Cleanroom

A prefabricated cleanroom is made of individual parts that are designed and planned such that they can be combined to create a finished structure. The configuration of a prefab cleanroom makes it possible to customize the cleanroom to fit specific and unique conditions that are required by users.

An additional factor that is often added to prefabricated or hardwall cleanrooms is two or more airlocks that workers pass through before entering the cleanroom. Airlocks are added as an extra level of protection to remove contaminants from workers and their clothing.

Softwall Cleanroom

Softwall cleanrooms are an economical cleanroom that is a flexible, mobile, and easy to install alternative to hardwall cleanrooms. They have a support frame made of steel or aluminum that is coated to protect the frame and extend its usage. The walls are made of strips of vinyl or polyvinyl chloride (PVC), which can be detached and replaced.

For softwall class 100 cleanrooms, two or more extensions may be necessary as pass throughs to maintain the class 100 classification. As with all class 100 cleanrooms, softwall cleanrooms have a unidirectional laminar airflow system that is supported by the cleanrooms frame.

Choosing the Right Class 100 Cleanroom Company

To make sure you have the most beneficial outcome when purchasing class 100 cleanrooms from a class 100 cleanroom company, it is important to compare at least 4 companies using our class 100 cleanroom directory. Each class 100 cleanroom company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each class 100 cleanroom company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple class 100 cleanroom companies with the same message.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services