Clean rooms are enclosed spaces inside which the level of contamination and pollutants like chemical vapors, dust and airborne microbes are reduced and controlled. Cleanrooms also control a wide range of environmental aspects and atmospheric conditions, such as air pressure, humidity, moisture and temperature. Read More…

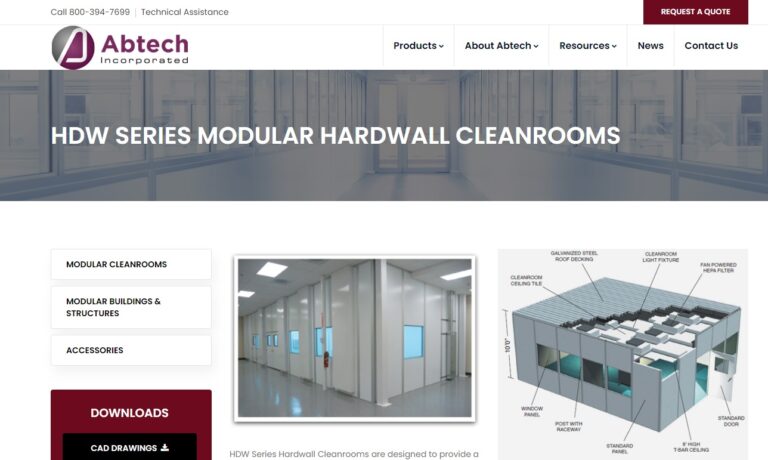

As a manufacturer of clean rooms, including inplant modular offices, exterior steel buildings, guard buildings, fork liftable and crane liftable buildings, multi-level buildings and mezzanines, Abtech offers turnkey installations or packages for install by end user. Our modular structures are constructed of steel, are free-standing & manufactured under strict quality control methods.

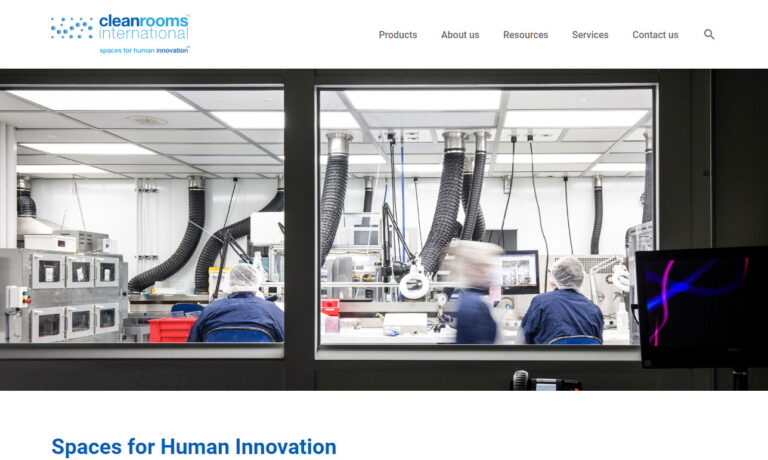

For the very best of clean rooms, look no further than Clean Rooms International! We can provide the ultimate in quality, customer service, durability, and unique designs just for you!

Cleanrooms By United is the industry’s premier manufacturer of modular clean room systems. We design, manufacture and install our clean rooms to meet our customers’ unique requirements. The custom, flexible, modular construction of our cleanrooms makes them easy to expand, reconfigure, or relocate as your cleanroom needs evolve.

Atmos-Tech Industries is a designer and manufacturer of cleanrooms and equipment for industries, including health care, pharmaceutical aerospace and automotive.

Our design staff is qualified with over 30 years of clean room experience. Our clean rooms are made from the highest quality materials and use a modular design that can be modified to suit any needs.

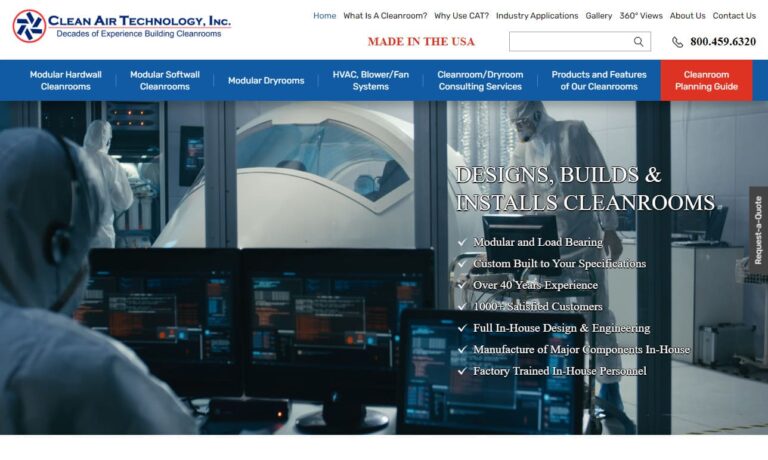

Our complete line of clean rooms will meet your needs. We are the experts of the clean room industry and our engineers can work with you to determine which clean room models work best for your business. We offer a variety of softwall, bio-clean, hardwall, and micro-clean options, all of which are manufactured with the highest standards. You will not be upset with our products. Contact us for more ...

Bayside Interiors is able to provide the design, engineering and construction of clean rooms. Bayside Interiors Inc. has been around since 1984. We also specialize in the construction of strut framing systems and facility support systems.

BASX Solutions has been designing and manufacturing truly modular cleanrooms since 1984. These are durable, scaleable, portable cleanrooms and are available in both softwall and hardwall designs. Our products meet the highest industry levels, from Class 100 to 100,000. Call for a free quick quote.

Since 1976, we at Mitchell Technical Sales have been dedicated to delivering excellence in quality cleanroom design, manufacturing, installation, certification, and maintenance. Our journey has been marked by innovation and expertise, ensuring that every project we undertake reflects our commitment to precision and cutting-edge solutions.

Welcome to Cleanrooms USA, where we pride ourselves on delivering unparalleled expertise and innovative solutions in the realm of cleanroom technology. At Cleanrooms USA, we are dedicated to providing cutting-edge cleanroom environments that meet the stringent requirements of industries ranging from pharmaceuticals and biotechnology to electronics and aerospace.

More Clean Rooms Manufacturers

The purpose of clean rooms is to create a control environment where users can develop and test critical components without contamination concerns. These rooms also enable users to replicate the conditions in which an item will be used. For instance, aerospace engineers can construct a clean room that mimics the air pressure, temperature, and gravity levels an aircraft or spacecraft will encounter. This controlled setting allows for more efficient testing and yields more accurate results.

Maintaining clean rooms is crucial for applications that demand immaculate air quality and particle-free environments. Such applications span across optics, aerospace, medical devices, biotechnology, software engineering, pharmacological research, infectious disease testing, and a wide range of medical research and product testing operations.

History of Clean Rooms

Cleanroom technology is a relatively recent development. The first cleanroom was created in 1960 by American physicist Willis Whitfield at the behest of Sandia National Laboratories. Sandia needed a solution to airborne contamination, especially in the aerospace, biotechnology, microtechnology, and medical fields. Before this invention, workers in these industries faced increasing disruptions from airborne contaminants like dust while handling small and delicate devices. Although similar spaces existed prior to Whitfield’s cleanroom, they were unreliable, had erratic airflow, and couldn’t effectively prevent air contamination. Whitfield’s cleanroom design revolutionized the field, enabling workers to consistently eliminate impurities with highly filtered air and maintain strict control over their working environment. Today, cleanroom manufacturing is crucial for producing everything from cell phones to spacecraft.

Types of Clean Rooms

Softwall Cleanroom

Softwall cleanrooms feature fabric walls, which can be made from free-hanging plastic strips or fabric stretched over a frame. To section off areas within the cleanroom, manufacturers use curtain dividers crafted from non-corrosive, non-fibrous materials that do not produce static electricity, like vinyl. These cleanrooms are highly portable and often designed in a modular fashion for easy assembly and disassembly.

Softwall cleanrooms are ideal for applications that don’t demand intense decontamination or the strictest environmental controls. While they can handle more demanding tasks, they require additional cleanroom equipment, such as air filters, to meet those higher standards.

Hardwall Cleanroom

Hardwall cleanrooms are built with a robust support frame and panels made from durable materials like stainless steel, welded steel, acrylic, tempered glass, and PVC. Unlike soft wall cleanrooms, they provide a more permanent solution. Often constructed using modular techniques, these cleanrooms offer superior environmental and contamination control.

Clean Lab

Clean labs are utilized in medical or pharmaceutical research. While they don’t always need FDA validation, clean rooms that manufacture medical and pharmaceutical products do. These labs can be either stationary or mobile. The required levels of contamination control, sterility, and environmental management depend on the presence of biohazards or materials that are explosive, flammable, or corrosive.

Positive Air Pressure Cleanroom

Positive air pressure cleanrooms are environments where more filtered air is introduced than is present outside, ensuring that contaminated air remains outside. These rooms are specifically designed for uses that do not involve hazardous substances, as the increased pressure causes some air to escape through walls, ceilings, or doors.

Negative Air Pressure Cleanroom

Negative air pressure cleanrooms operate by creating a vacuum effect to expel contaminated air from the room. After the air is removed, it is replenished with clean air, which can come from either the filtered evacuated air or fresh air that has been filtered. These cleanrooms are essential for applications involving hazardous chemicals, including biohazards and flammable or potentially explosive substances.

Modular Cleanroom

A modular clean room consists of factory-pre-cut components assembled on-site, offering a flexible solution that can be quickly disassembled and reassembled as needed. This design is prized for its cost-effectiveness, simple construction, and versatility.

Modular clean rooms are essential in manufacturing and research facilities where maintaining a controlled environment is critical. They are particularly crucial in pharmaceutical and medical industries, which demand high cleanliness standards. These rooms minimize contaminants like dust, airborne microbes, aerosols, and chemical vapors. The air quality is measured by particle count and size, making modular clean rooms beneficial for applications sensitive to small particles.

Portable Cleanroom

Portable cleanrooms, mounted on casters for easy movement, are essential for raw material testing in pharmaceutical manufacturing. The pharmaceutical sector relies on cleanrooms to meet strict standards for medicine production, ensuring each stage of the process occurs in sterile, contamination-free environments. These design-build portable cleanrooms act as quarantine zones for raw materials until quality control tests are completed.

Customizable to ISO 5-8 cleanroom standards, they come in various sizes and materials. Frames can be constructed from steel or aluminum, while walls may combine solid and fabric elements. Soft material strip walls facilitate the entry and exit of forklifts transporting raw materials. Additionally, specific air change rates can be tailored for each cleanroom.

Advantages of Modular Cleanrooms Over Stick-Built Cleanrooms

Investing in a cleanroom is a significant capital expenditure, requiring a comprehensive analysis during the budgeting process. Every factor plays a crucial role in determining the return on investment. Opting for a cheaper option doesn’t necessarily translate to savings. An initial low-cost purchase can prove costly when accounting for time, labor, and quality. Although cleanroom costs fluctuate based on process requirements, modular cleanrooms consistently outperform stick-built cleanrooms in nearly every scenario.

- Modular cleanrooms offer high flexibility. Modular cleanrooms offer easy reconfiguration, expansion, and relocation, unlike stick-built counterparts. Structural adjustments in stick-built cleanrooms necessitate invasive and complex procedures, resulting in significant time and cost expenditures.

- Modular cleanrooms have a shorter turnaround time. They can be constructed 30% to 50% faster than traditional stick-built structures. They utilize standard materials and typically need minimal or no modification during installation. Additionally, modular construction produces minimal dust, significantly cutting down on clean-up time and enabling quicker start-up of operations.

- Modular cleanrooms are associated with tax savings. Modular cleanrooms are categorized as capital equipment rather than building or leasehold improvements like stick-built cleanrooms. This classification allows modular cleanrooms to benefit from accelerated depreciation, leading to potential tax savings.

A modular cleanroom system is worth the upfront price if it has the following characteristics.

Durability. High-pressure laminate (HPL) stands out as a superior choice for modular cleanroom wall and ceiling panels. Featuring a robust exterior of high-pressure plastic laminate and an inner core of resin-impregnated cellulose fibers, these panels offer a non-porous surface, ensuring excellent hygiene standards. Their exceptional durability provides high resistance to impacts and wear. By opting for long-lasting materials like HPL, maintenance costs are minimized, translating into significant savings over time.

Excellent Design. HPL panels are effortlessly customizable for integrating accessories like intercoms, switches, and air return grilles. Their anti-scratch feature ensures a long-lasting appearance. Additionally, modular cleanroom suppliers ensure compliance with GMP and FDA standards, tailoring cleanrooms precisely to meet client-specific needs.

Easily Cleaned. HPL panels demonstrate robust resistance to sanitizing agents, simplifying their cleaning process. They maintain integrity when exposed to aggressive cleaning agents, ensuring durability even if scratched. This durability not only enhances longevity but also lowers maintenance expenses.

Clean Room Equipment Components

Inside clean rooms, you’ll typically find an air quality control system comprising air filters, fans, and pumps. The most meticulously maintained clean rooms employ directional air filters to promote laminar airflow. This controlled airflow ensures a continuous cycle of fresh, filtered air into the room while expelling any remaining contaminants. Commonly used filters include High Efficiency Particulate Air (HEPA) filters, capable of trapping particles as small as 0.3 microns, and Ultra Low Particulate Air (ULPA) filters, known for their even more stringent performance.

Cleanroom furniture such as cleanroom tables, cleanroom walls, laminar flow benches, and laminar flow hoods are often fixtures within these environments.

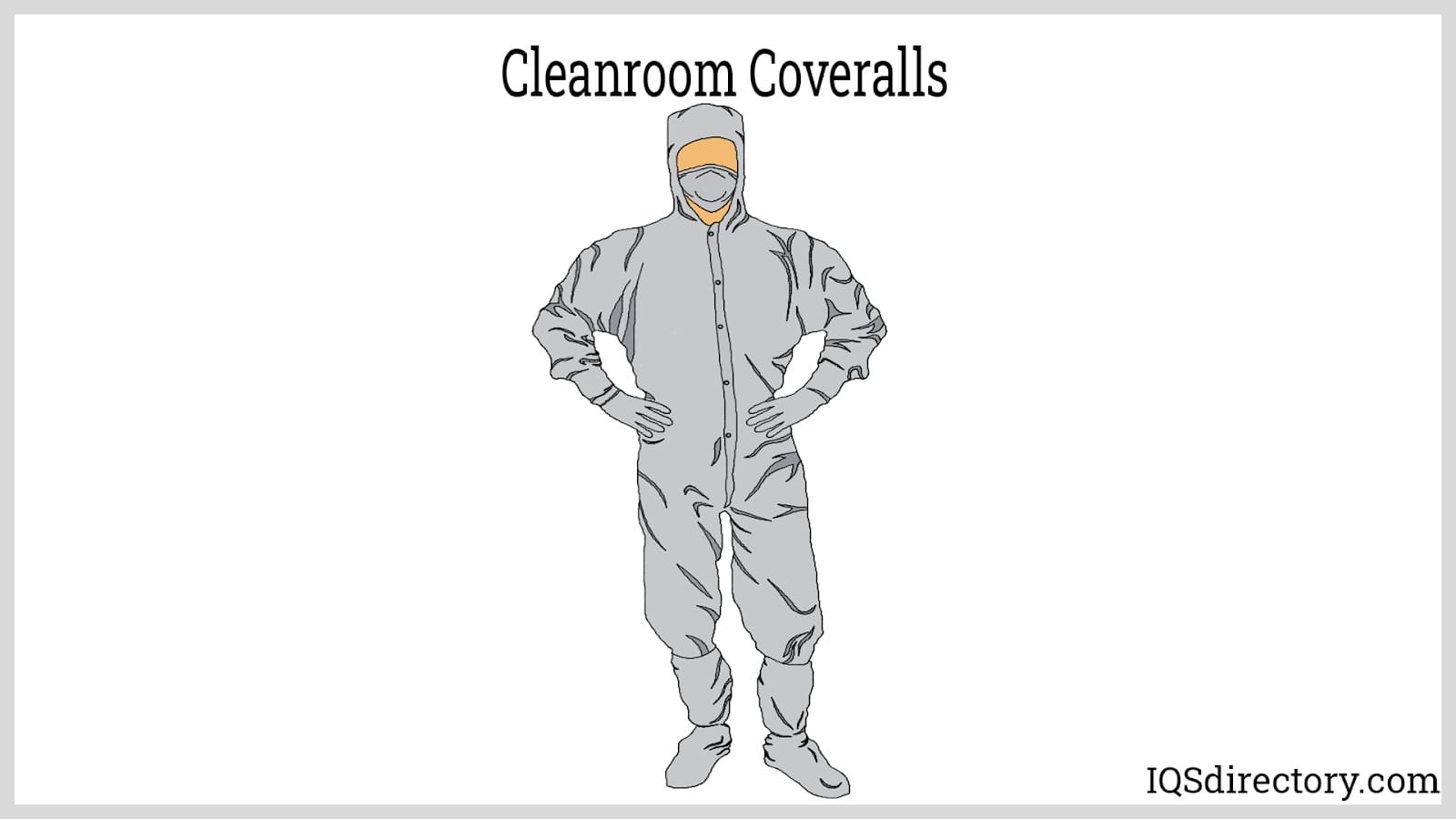

To prevent the introduction of particles, operators and staff must wear appropriate clean room attire. Human skin sheds approximately 100,000 dead skin cells per minute even when stationary! Attire includes garments that cover human skin and hair, which are about 100 micrometers wide, such as shoe covers, beard covers, bouffant caps, face masks, and approved cleaning wipes. Furthermore, personnel may use air showers—small rooms where they rinse off before entering the clean room—to enhance these efforts.

Clean Room Benefits

Cleanrooms offer significant advantages for various applications. Firstly, by eliminating impurities, they drastically reduce the risk of system malfunctions or product breakdowns. Secondly, they enable the handling of highly sensitive materials and technologies that would otherwise be compromised, ensuring accuracy, safety, and efficiency in your work. Additionally, cleanrooms allow you to create controlled microenvironments around your products. For example, maintaining constant positive pressure prevents contamination, while controlling humidity minimizes electrostatic discharge. Ultimately, leveraging these benefits not only saves time, money, and energy but also enhances your reputation for delivering superior work or products.

Cleanroom Design and Customization

When designing a clean room, manufacturers focus on creating a controlled environment that effectively excludes particulates. The approach taken varies based on the specific application and its requirements. Clean rooms can be permanent fixtures integrated into building structures, enclosed by clear plastic walls or glass. Alternatively, they may feature a portable or modular design.

Manufacturers tailor their designs in terms of size and materials used. Some clean rooms are as large as warehouses, suitable for microelectronics, circuitry, and pharmaceutical manufacturing—often referred to as “ballrooms”. Conversely, others are compact, resembling home kitchen ovens, designed for small-scale medical testing, repairs, or specialized operations.

Materials selected for use in the clean room must adhere strictly to specific criteria to ensure the room’s effectiveness, particularly in preventing air contamination. Like softwall clean room materials, general materials must be non-fibrous, non-static electricity-generating, and non-corrosive. Even stainless steel, which is commonly used, can be problematic as it may corrode upon exposure to bleach. Typical materials used for clean room components include:

- Acrylic: Economical, easy to clean, tintable, and possesses great tensile strength.

- Static Dissipative PVC: Guards against electrostatic discharge and particulate contamination.

- Polycarbonate: High tensile strength, shatter-resistant, and resistant to acids, cleaning solutions, and solvents.

- Tempered Glass: Clear, chemically resistant, non-porous, and easy to clean.

- Polypropylene: Offers superior resistance to chemicals and acids.

Manufacturers offer an extensive array of custom cleanroom supplies and accessories to enhance your cleanroom system. These include electric heaters, smoke detectors, intercoms, door interlocks, central vacuum systems, cleanroom foggers, ductwork, electrical outlets, process piping, and top decks, among others.

Clean Room Safety and Compliance Standards

Clean rooms are assessed based on expected contaminant management levels. Manufacturers of cleanrooms may opt to gauge and categorize them according to one of four safety and compliance standards: US FED STD 209E, ISO 14644-1, EMP EU, and BS 5295.

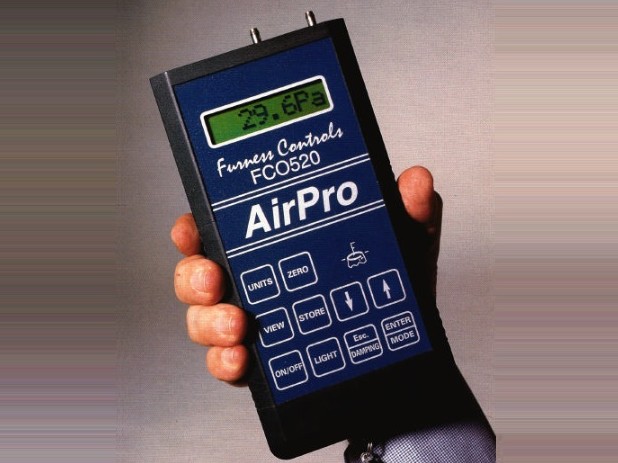

Clean rooms classified according to US FED STD 209E are categorized based on the concentration of 0.5-plus micrometer-sized particles per cubic foot of air. The classification numbers indicate the permissible particle count, with higher numbers allowing more particles in the air. Manufacturers select clean rooms based on their specific application requirements. For instance, processes that could trigger chemical reactions or environmental wear necessitate a Class 100 clean room, constructed from materials that minimize fibrous contaminants. Conversely, less sensitive applications, like those involving soft materials such as plastics or flexible acrylics, may opt for a Class 10,000 clean room, featuring softer walls and less stringent controls. Particle counts are monitored using discrete particle counting devices.

Clean rooms, graded on a scale from three to eight according to International Organization for Standardization (ISO) standards, achieve varying levels of cleanliness, with ISO Class 3 being the most stringent. For instance, an ISO Class 5 clean room allows up to 100,000 particles per cubic meter, equating to a Class 100 US Federal Standard (FED) clean room for reference.

Additionally, industries in the European Union often adhere to EMP EU standards, while British cleanroom standards like BS 5295 are also utilized, measuring contaminants per cubic meter rather than cubic foot, the standard in the USA.

Your clean room must meet basic standards, but additional certifications may be necessary based on your industry and application, especially with FDA regulations. Industries like medical devices adhere to ISO and US Federal standards. To determine your specific requirements, consult your manufacturer, industry experts, or relevant governmental bodies.

Things to Consider Regarding Clean Rooms

If you’re contemplating buying a clean room or clean room products, several factors warrant your consideration. Begin by defining your application and goals. These aspects will guide your search for specific features in the clean room, such as modularity, softwall paneling, sprinklers, humidifiers, blowers/fans, windows, and more. They’ll also determine the level of contamination and environmental control necessary for your needs.

Once armed with your list of specifications, your next crucial step involves connecting with a reputable clean room supplier or manufacturer. Remember, selecting the right manufacturer goes beyond mere product availability and pricing; it hinges on exemplary customer service. You need a manufacturer who not only listens attentively but also prioritizes your best interests throughout the project. Look for a partner who is committed to going above and beyond for you. Explore our curated directory featuring profiles, website links, request for quote options, and contact details of some of the industry’s most respected contract manufacturers and suppliers.

Check out our Environmental Test Chambers website

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services