A clean room’s design and equipment affect its performance. Properties like structural design, air filter and vent position, air filter and vent composition, and all other properties related to a clean room’s configuration affect decontamination capacity. The higher the decontamination standard, the more vigorously controlled each of a clean room’s properties must be. Read More…

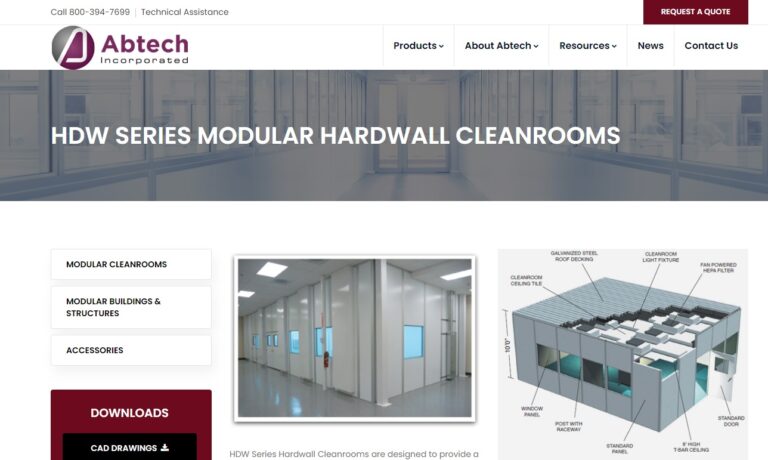

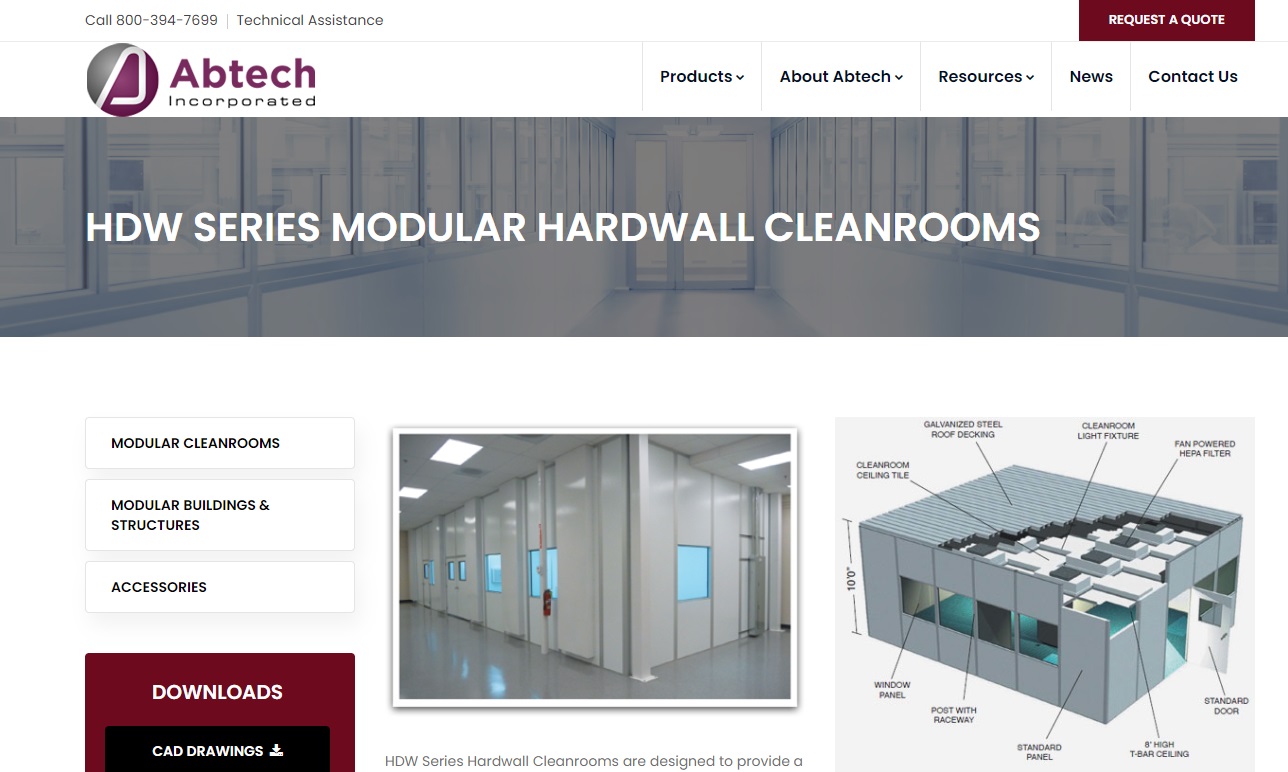

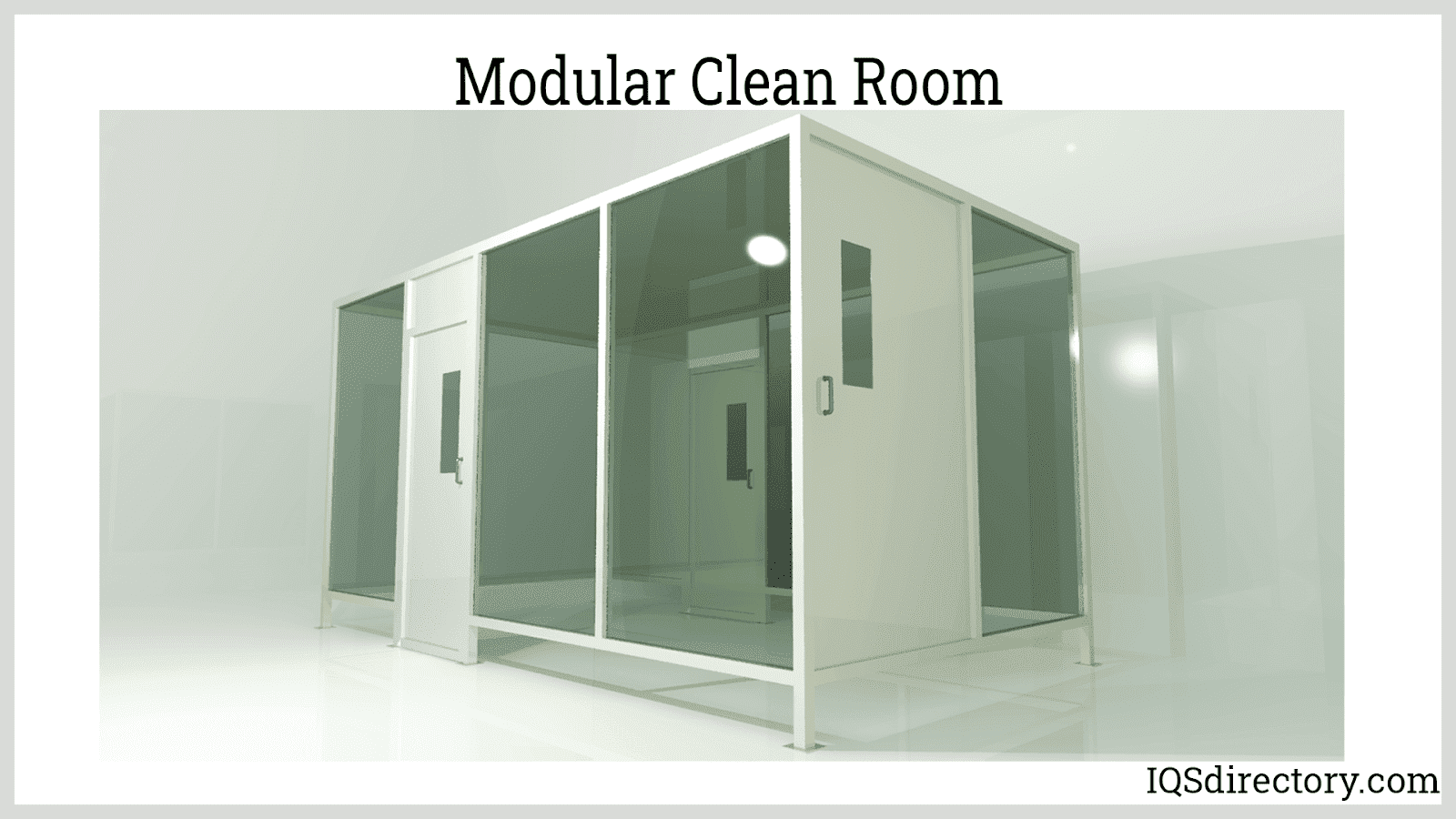

As a manufacturer of clean rooms, including inplant modular offices, exterior steel buildings, guard buildings, fork liftable and crane liftable buildings, multi-level buildings and mezzanines, Abtech offers turnkey installations or packages for install by end user. Our modular structures are constructed of steel, are free-standing & manufactured under strict quality control methods.

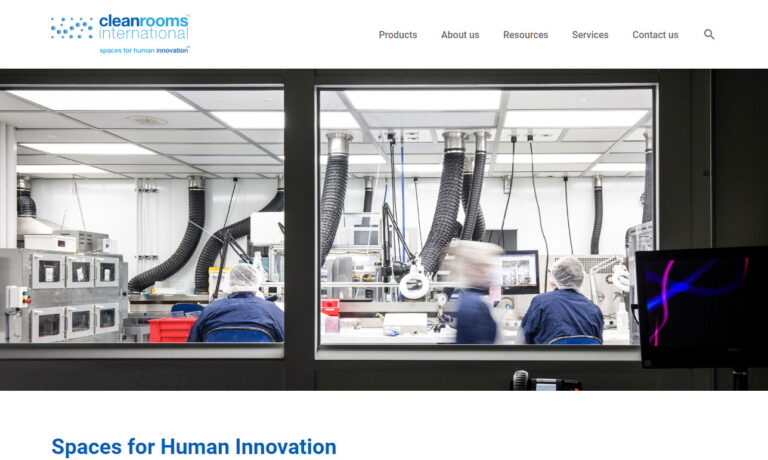

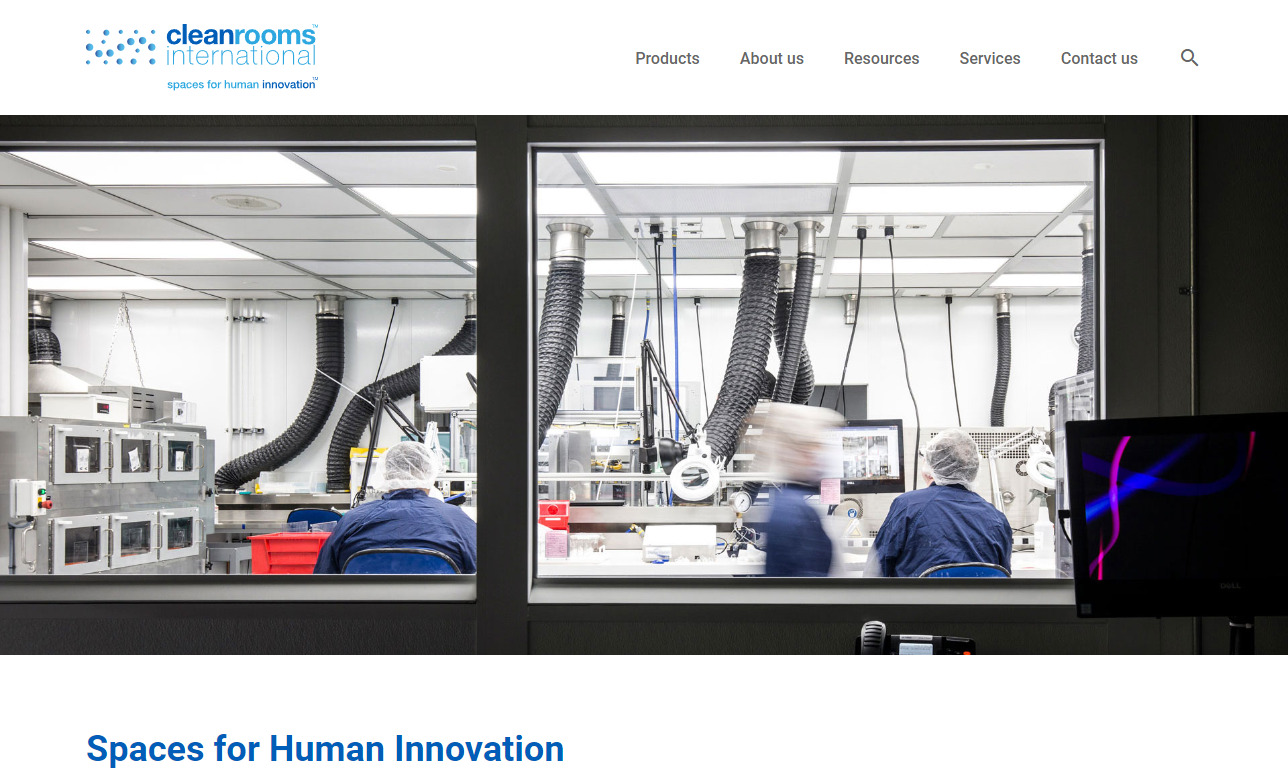

For the very best of clean rooms, look no further than Clean Rooms International! We can provide the ultimate in quality, customer service, durability, and unique designs just for you!

Cleanrooms By United is the industry’s premier manufacturer of modular clean room systems. We design, manufacture and install our clean rooms to meet our customers’ unique requirements. The custom, flexible, modular construction of our cleanrooms makes them easy to expand, reconfigure, or relocate as your cleanroom needs evolve.

Atmos-Tech Industries is a designer and manufacturer of cleanrooms and equipment for industries, including health care, pharmaceutical aerospace and automotive.

Our design staff is qualified with over 30 years of clean room experience. Our clean rooms are made from the highest quality materials and use a modular design that can be modified to suit any needs.

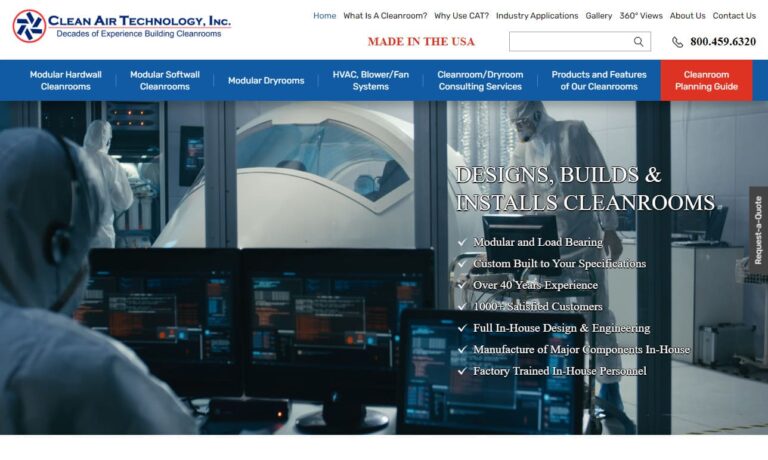

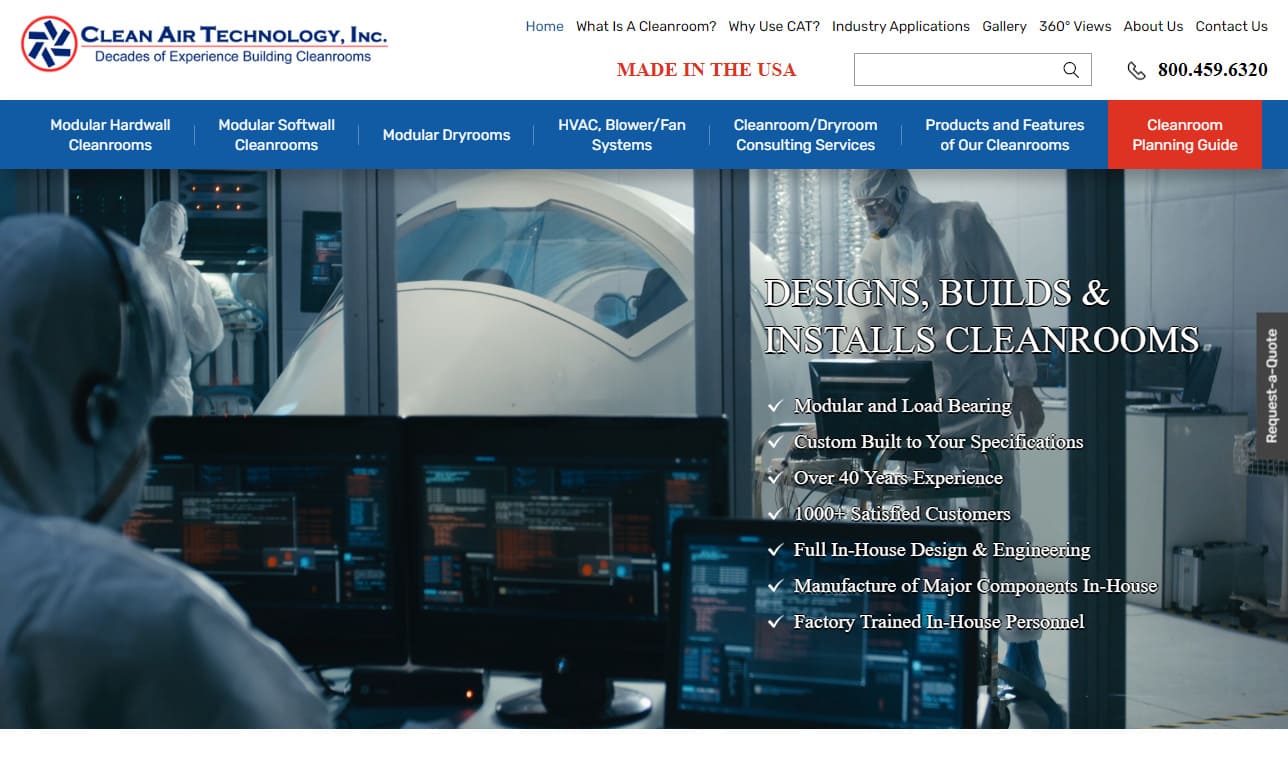

Our complete line of clean rooms will meet your needs. We are the experts of the clean room industry and our engineers can work with you to determine which clean room models work best for your business. We offer a variety of softwall, bio-clean, hardwall, and micro-clean options, all of which are manufactured with the highest standards. You will not be upset with our products. Contact us for more ...

Bayside Interiors is able to provide the design, engineering and construction of clean rooms. Bayside Interiors Inc. has been around since 1984. We also specialize in the construction of strut framing systems and facility support systems.

BASX Solutions has been designing and manufacturing truly modular cleanrooms since 1984. These are durable, scaleable, portable cleanrooms and are available in both softwall and hardwall designs. Our products meet the highest industry levels, from Class 100 to 100,000. Call for a free quick quote.

Since 1976, we at Mitchell Technical Sales have been dedicated to delivering excellence in quality cleanroom design, manufacturing, installation, certification, and maintenance. Our journey has been marked by innovation and expertise, ensuring that every project we undertake reflects our commitment to precision and cutting-edge solutions.

Welcome to Cleanrooms USA, where we pride ourselves on delivering unparalleled expertise and innovative solutions in the realm of cleanroom technology. At Cleanrooms USA, we are dedicated to providing cutting-edge cleanroom environments that meet the stringent requirements of industries ranging from pharmaceuticals and biotechnology to electronics and aerospace.

More Cleanroom Supply Manufacturers

Portable and modular clean rooms, for example, are generally not capable of generating the extremely low decontamination levels that are possible in permanent clean rooms. For this reason, they are less likely to employ light-scattering particle measurement equipment or any of the other kinds of advanced equipment installed in more advanced clean rooms.

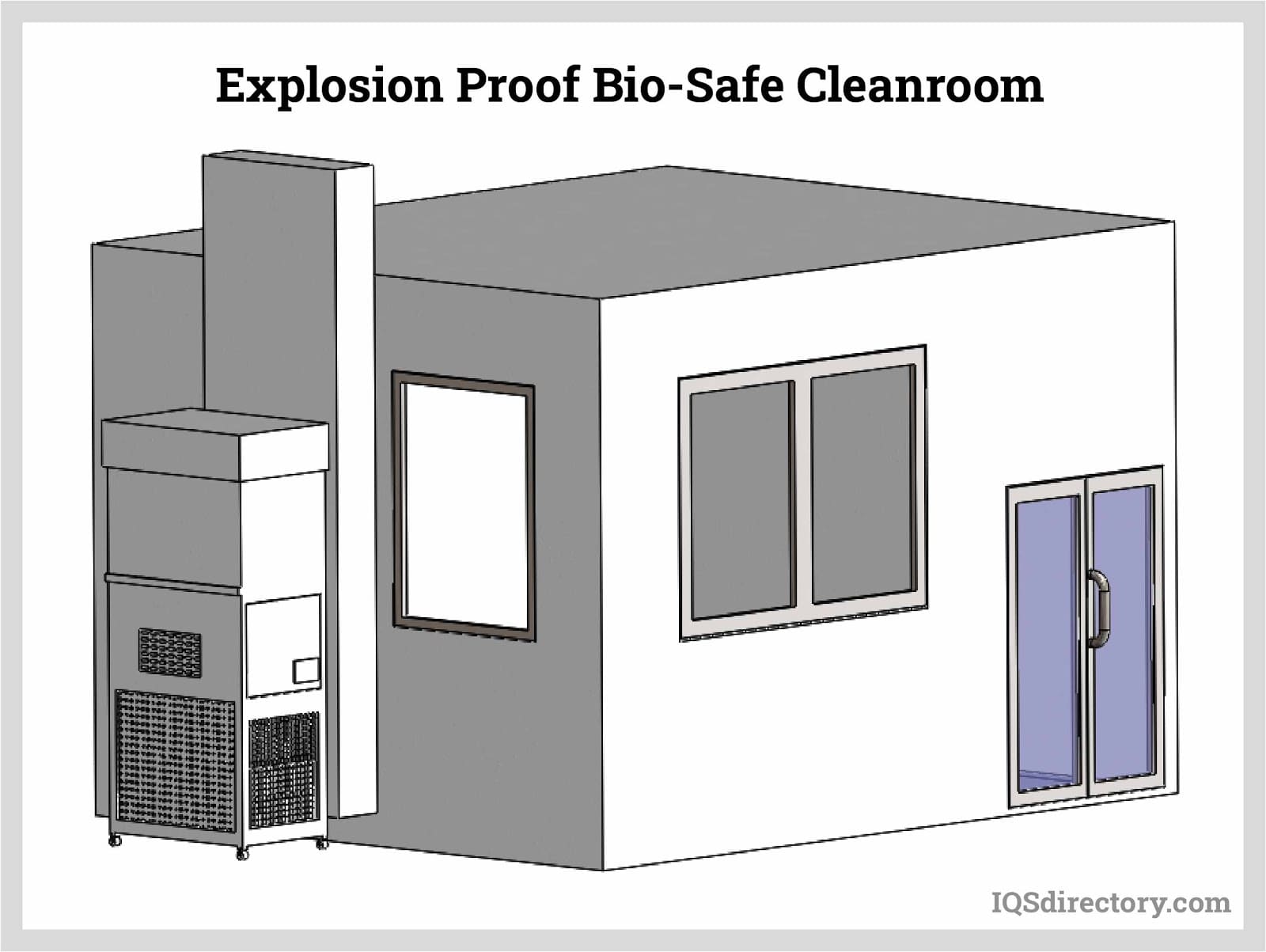

But as the decontamination standard of a clean room rises, the impact that all clean room supplies have on performance also increases. Infectious disease research laboratories, which require highly controlled testing environments, make use of harsh sterilization chemicals. Work surfaces in those environments must be corrosion-resistant so as not to contaminate test samples with vapors or particulates generated by corrosion. Stainless steel, for example, can corrode if exposed to bleach.

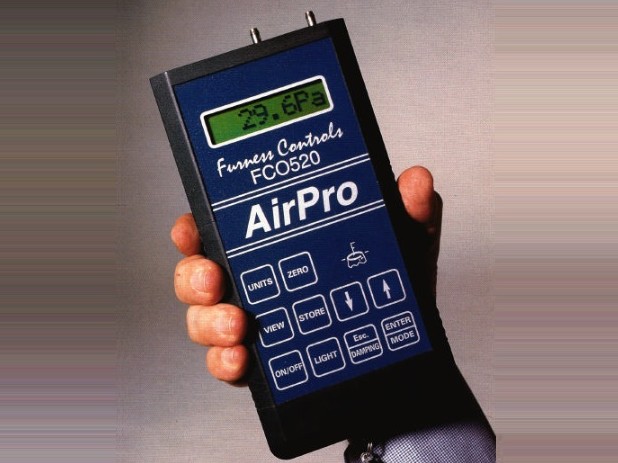

Clean room supplies must be selected carefully because of the strictness of the standards set for clean room operation. The United States government, the ISO and other international standard-setting organizations assign ratings and classes to clean rooms depending on their capacity for decontamination.

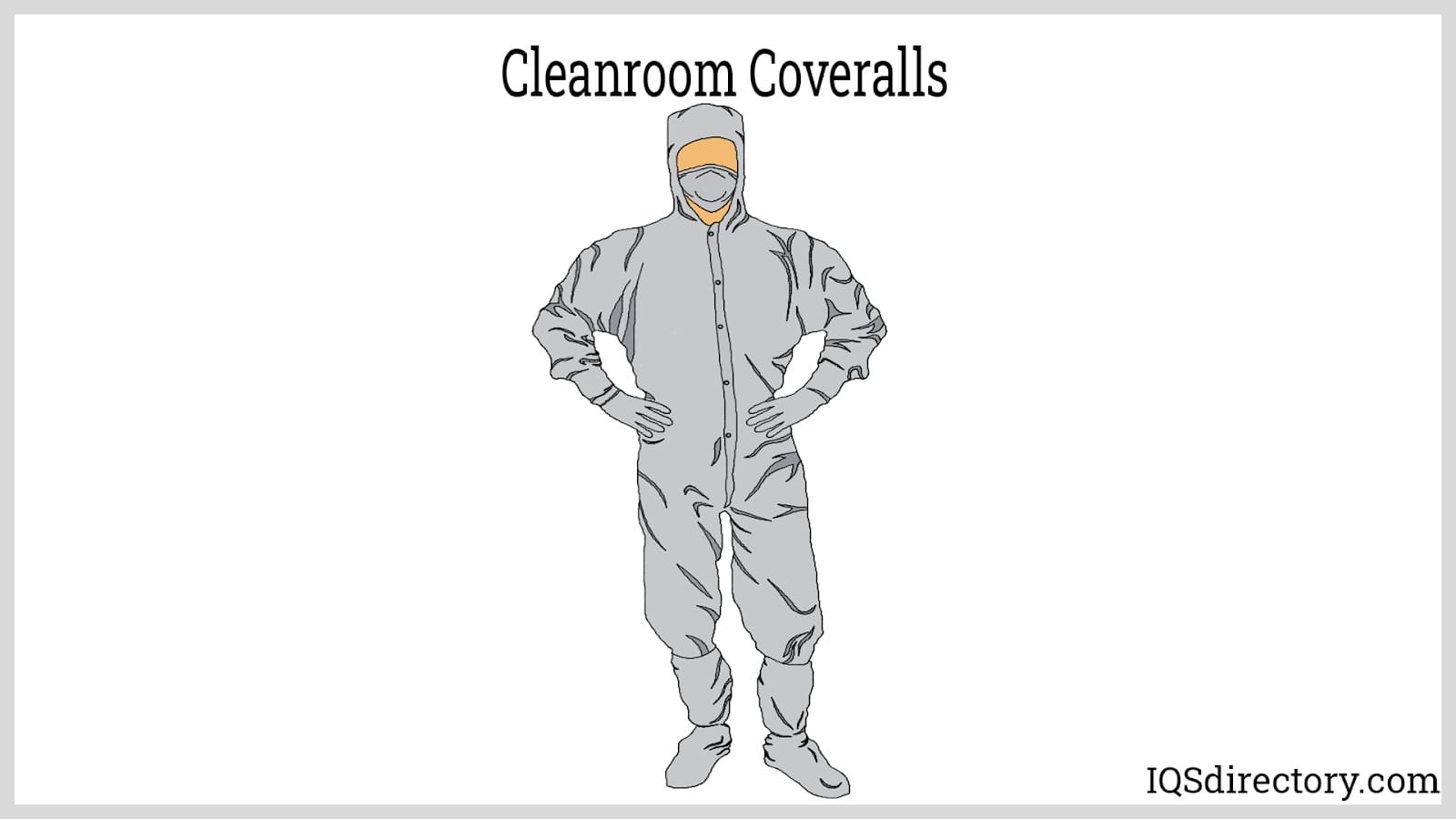

US FED STD 209E standards rate clean rooms based on how many 0.5 micrometer-sized particles per cubic foot are considered acceptable within a given clean room. Class 1 clean rooms contain no more than one 0.5 micrometer-sized particle per cubic foot. This is an extremely low contamination level, and in order to achieve it, no fibrous building materials, furniture, or clean room clothing can be brought into the enclosure. Even certain kinds of paper cannot be brought into Class 1 clean rooms because of some paper varieties' fibrous qualities. Some clean rooms are equipped with adhesive mats designed to pick up particles on the floor that may have been tracked in by workers.

Such advanced clean rooms employ complex combinations of filters, monitoring equipment, and other methods of keeping contamination low, but every factor contributes to the capacity of a clean room to become decontaminated.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services