Clean rooms are specialized environments designed to minimize the presence of particulate matter, bacteria, and other harmful substances. They are used in industries where cleanliness is of utmost importance, such as semiconductors, pharmaceuticals, aerospace research, medical device manufacturing, and food packaging. In this article, we will explore the components of clean rooms, their construction, classifications, benefits, and applications. Read More…

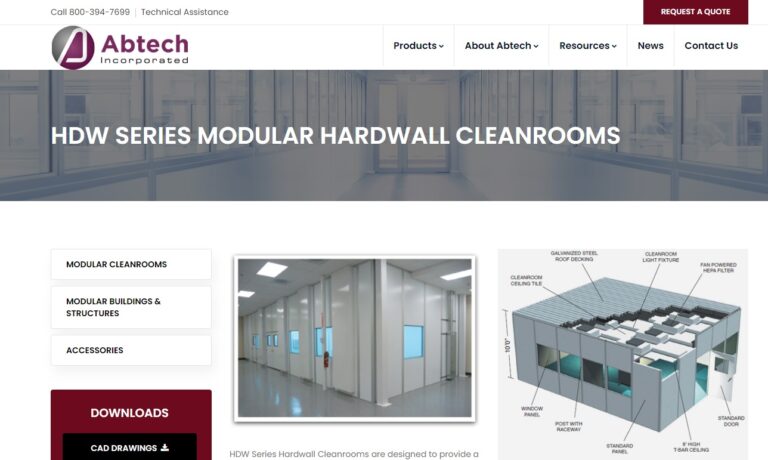

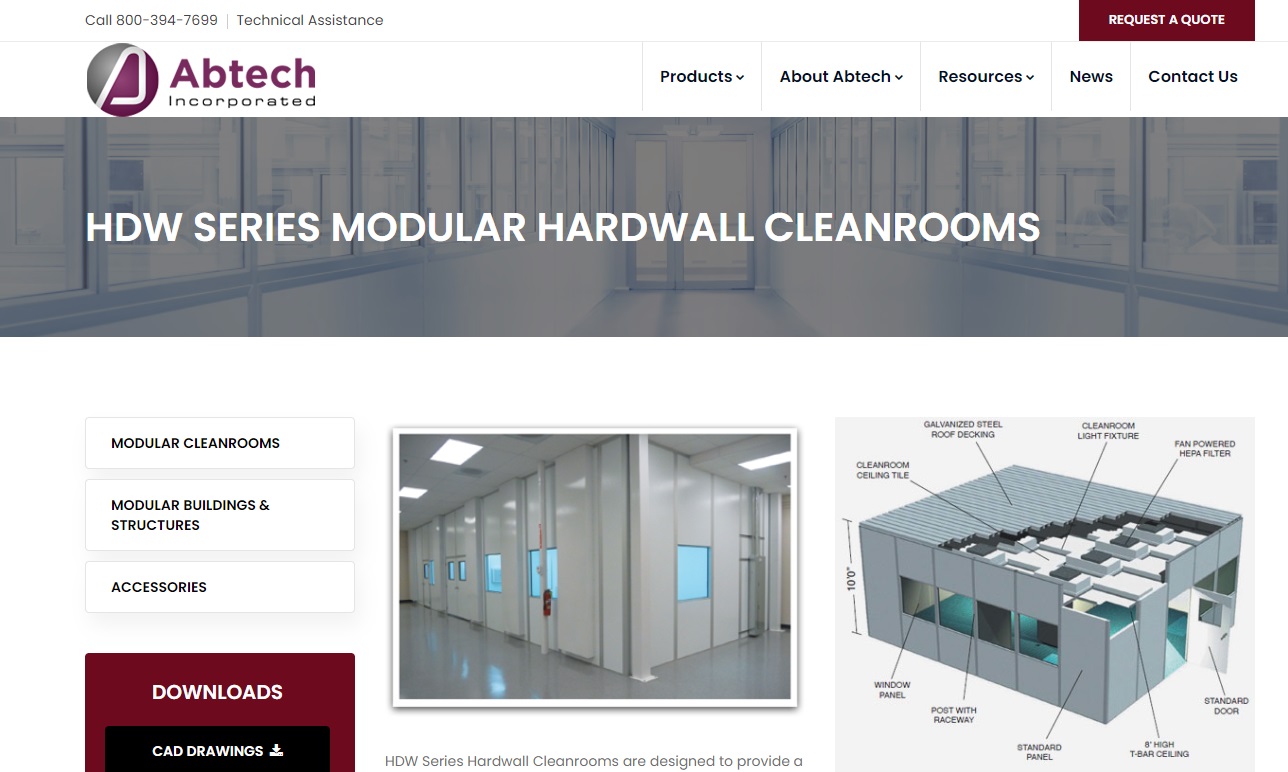

As a manufacturer of clean rooms, including inplant modular offices, exterior steel buildings, guard buildings, fork liftable and crane liftable buildings, multi-level buildings and mezzanines, Abtech offers turnkey installations or packages for install by end user. Our modular structures are constructed of steel, are free-standing & manufactured under strict quality control methods.

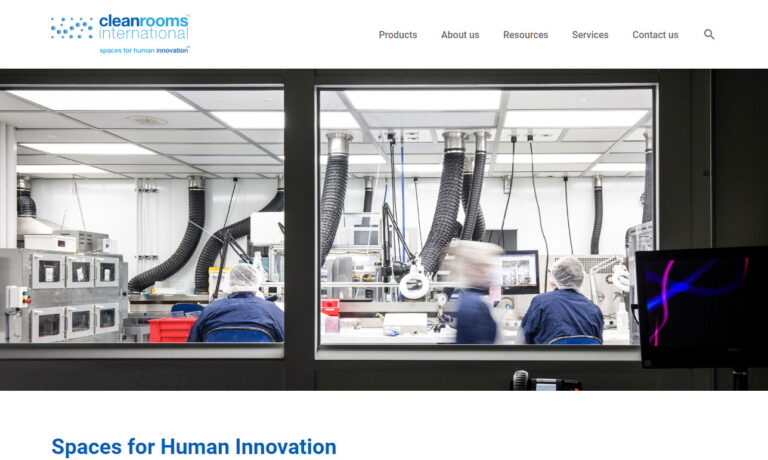

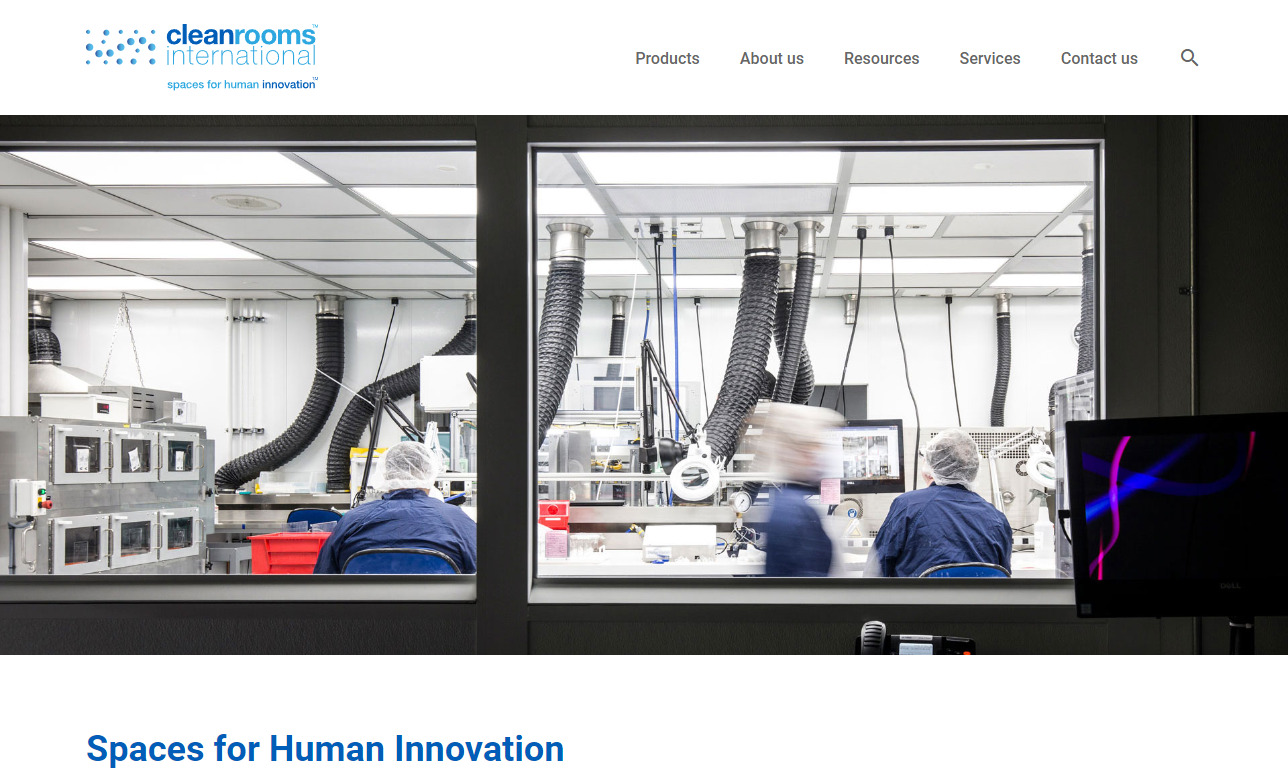

For the very best of clean rooms, look no further than Clean Rooms International! We can provide the ultimate in quality, customer service, durability, and unique designs just for you!

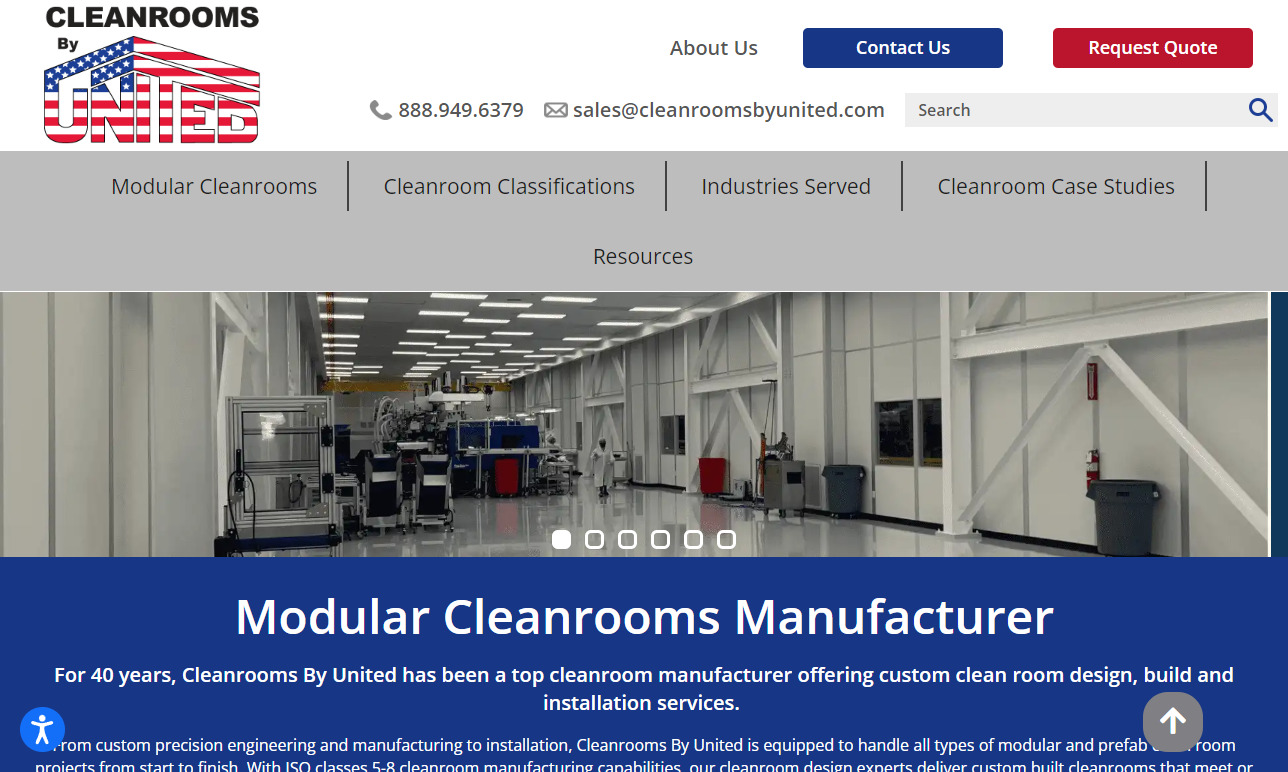

Cleanrooms By United is the industry’s premier manufacturer of modular clean room systems. We design, manufacture and install our clean rooms to meet our customers’ unique requirements. The custom, flexible, modular construction of our cleanrooms makes them easy to expand, reconfigure, or relocate as your cleanroom needs evolve.

Atmos-Tech Industries is a designer and manufacturer of cleanrooms and equipment for industries, including health care, pharmaceutical aerospace and automotive.

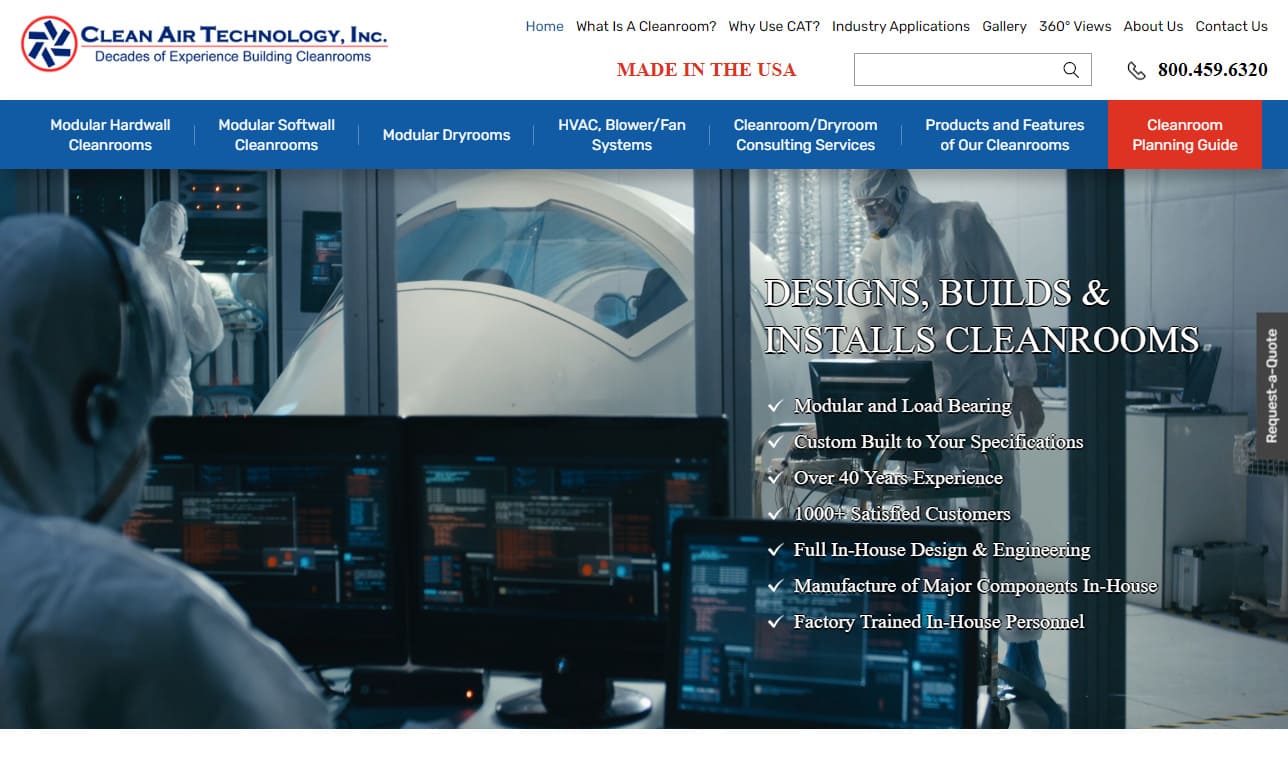

Our design staff is qualified with over 30 years of clean room experience. Our clean rooms are made from the highest quality materials and use a modular design that can be modified to suit any needs.

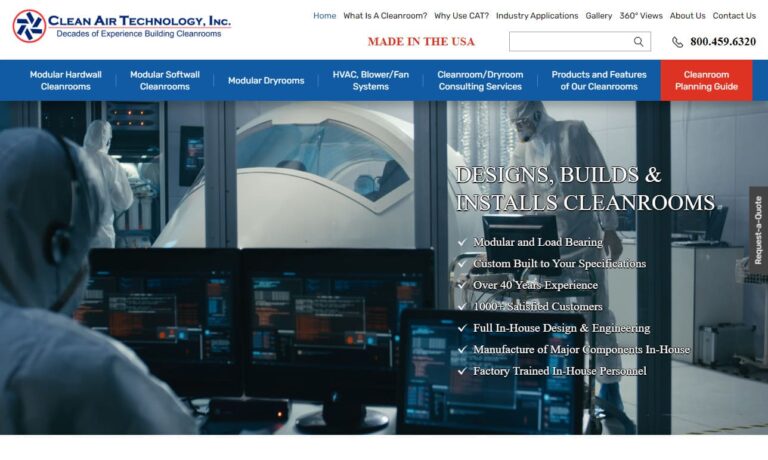

Our complete line of clean rooms will meet your needs. We are the experts of the clean room industry and our engineers can work with you to determine which clean room models work best for your business. We offer a variety of softwall, bio-clean, hardwall, and micro-clean options, all of which are manufactured with the highest standards. You will not be upset with our products. Contact us for more ...

Bayside Interiors is able to provide the design, engineering and construction of clean rooms. Bayside Interiors Inc. has been around since 1984. We also specialize in the construction of strut framing systems and facility support systems.

BASX Solutions has been designing and manufacturing truly modular cleanrooms since 1984. These are durable, scaleable, portable cleanrooms and are available in both softwall and hardwall designs. Our products meet the highest industry levels, from Class 100 to 100,000. Call for a free quick quote.

Since 1976, we at Mitchell Technical Sales have been dedicated to delivering excellence in quality cleanroom design, manufacturing, installation, certification, and maintenance. Our journey has been marked by innovation and expertise, ensuring that every project we undertake reflects our commitment to precision and cutting-edge solutions.

Welcome to Cleanrooms USA, where we pride ourselves on delivering unparalleled expertise and innovative solutions in the realm of cleanroom technology. At Cleanrooms USA, we are dedicated to providing cutting-edge cleanroom environments that meet the stringent requirements of industries ranging from pharmaceuticals and biotechnology to electronics and aerospace.

More Cleanroom Construction Manufacturers

Components of Clean Rooms

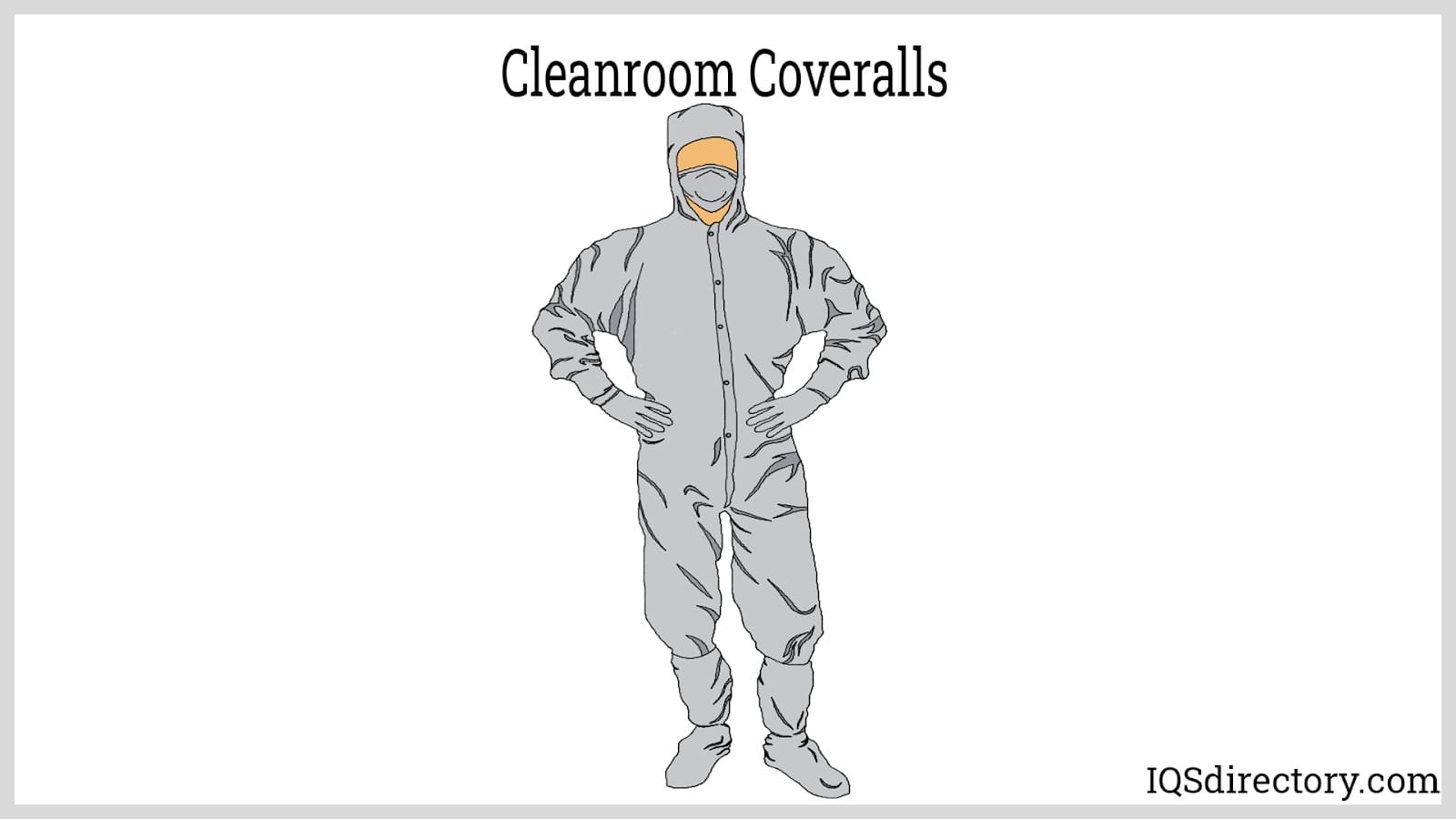

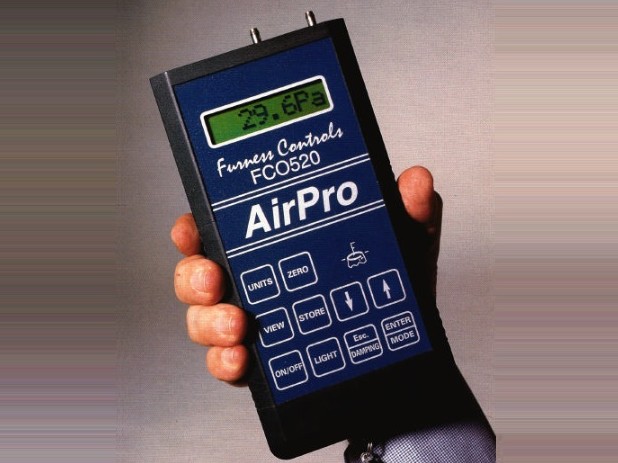

All clean rooms have some common components, including walls, ceilings, and floors, HVAC systems, lighting, filters, positive pressure, cleanroom garments, cleanroom furniture, and monitoring systems. Walls, ceilings, and floors are made from non-porous materials that are easy to clean and disinfect. HVAC systems control the temperature, humidity, and airflow in the clean room, ensuring a stable and consistent environment. Lighting is designed to minimize shadows and glare, making it easier for workers to see what they're doing. Filters remove airborne particles, bacteria, and other contaminants from the air, ensuring a clean environment. Positive pressure ensures that air flows from the clean room to the outside environment, preventing contaminants from entering. Cleanroom garments are specialized clothing worn by workers to minimize the shedding of particles. Cleanroom furniture is designed to be easy to clean and disinfect. Monitoring systems are used to measure and control the environmental conditions in the clean room.

Methods of Constructing Clean Rooms

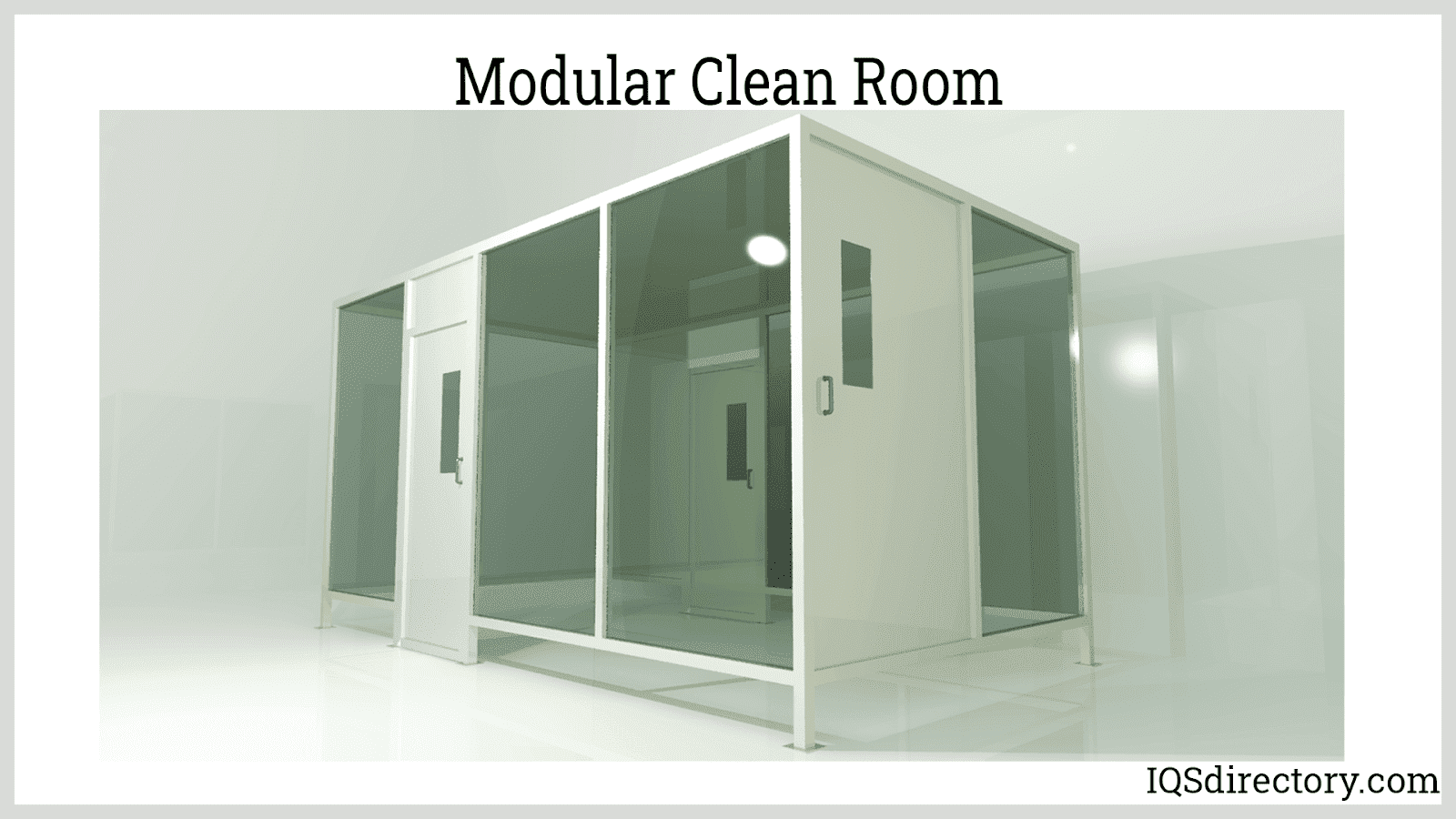

Clean rooms can be constructed using different methods, including conventional stick-built, modular, softwall, and rigidwall. Conventional stick-built clean rooms are constructed from scratch on-site, with each component customized and installed by construction workers. Modular clean rooms are pre-fabricated in a factory and then assembled on-site like building blocks. Softwall clean rooms use flexible materials like vinyl to create a barrier between the clean room and the surrounding environment. Rigidwall clean rooms use solid, non-porous materials like steel to construct walls, ceilings, and floors. The selection of the appropriate construction method depends on factors such as budget, space, and regulatory requirements.

Classifications of Clean Rooms and Their Construct

Clean rooms are classified based on the number of particles per cubic meter of air in the room, with ISO Class 1 being the cleanest and ISO Class 4 being the least clean. Here are brief descriptions of each ISO Class of clean room:

- ISO Class 1: The highest level of clean room classification, with a maximum particle count of 10 particles per cubic meter of air.

- ISO Class 2: Maximum particle count of 100 particles per cubic meter of air.

- ISO Class 3: Maximum particle count of 1,000 particles per cubic meter of air.

- ISO Class 4: Maximum particle count of 10,000 particles per cubic meter of air.

- ISO Class 5: Maximum particle count of 100,000 particles per cubic meter of air.

- ISO Class 6: Maximum particle count of 1,000,000 particles per cubic meter of air.

- ISO Class 7: Maximum particle count of 10,000,000 particles per cubic meter of air.

- ISO Class 8: Maximum particle count of 100,000,000 particles per cubic meter of air.

As a result, construction methods and materials used for each level of clean room classification can vary. For example, for ISO Class 1 clean rooms, the construction may involve specialized materials such as high-performance filter systems, stainless steel walls, and floors, and specialized lighting systems to maintain the required level of cleanliness. For ISO Class 4 clean rooms, meanwhile, the construction may involve standard construction materials and methods, but with additional air filtration systems and regular cleaning procedures to maintain the required level of cleanliness. It is important to select the appropriate construction method and materials for the required level of cleanliness to ensure compliance with regulatory standards and the desired level of product quality.

Considerations Regarding Clean Rooms

Although clean rooms have many benefits, there are some negative considerations to take into account. Firstly, the construction and maintenance of clean rooms can be expensive, and the initial investment can be substantial. Secondly, clean rooms require complex maintenance procedures, and workers need to be trained to operate and maintain them correctly. Thirdly, access to clean rooms is often restricted, with workers required to undergo specialized training and use specialized equipment. Finally, the use of clean rooms can be time-consuming, slowing down production processes and increasing costs.

Benefits of Clean Rooms

Despite the negative considerations, the benefits of clean rooms are significant. The primary benefit of clean rooms is the reduction of contamination, ensuring that products are of high quality and meet regulatory standards. Clean rooms also enable precision manufacturing, with products manufactured to exact specifications. Enhanced productivity is another benefit of clean rooms, with workers able to work in a clean and organized environment. Quality assurance is also improved, with fewer defects and errors in products.

Applications of Clean Rooms

Once constructed, clean rooms have a wide range of applications. Many of these applications, including their unique construction are discussed below.

Semiconductor Manufacturing

Clean rooms used in semiconductor manufacturing require a very high level of cleanliness, typically ISO Class 1 or 2. The construction of clean rooms for this application involves specialized materials such as high-performance filter systems, stainless steel walls and floors, and specialized lighting systems. The air handling system of these clean rooms is designed to move air vertically to reduce the risk of contamination. Specialized HVAC systems are also required to maintain precise temperature and humidity levels.

Pharmaceutical Manufacturing

Clean rooms used in pharmaceutical manufacturing typically require an ISO Class 5 or better level of cleanliness. The construction of clean rooms for this application involves materials such as stainless steel, epoxy flooring, and HEPA filtration systems. The HVAC system is designed to ensure proper air pressure differentials to prevent contamination from outside the clean room. The lighting systems are also designed to minimize the generation of particles.

Aerospace Research

Clean rooms used in aerospace research typically require an ISO Class 7 or 8 level of cleanliness. The construction of clean rooms for this application involves materials such as aluminum, epoxy flooring, and HEPA filtration systems. The HVAC system is designed to control temperature, humidity, and air exchange rate. Airflow patterns are also carefully controlled to minimize contamination.

Medical Device Manufacturing

Clean rooms used in medical device manufacturing typically require an ISO Class 7 or 8 level of cleanliness. The construction of clean rooms for this application involves materials such as vinyl flooring, aluminum walls, and ceiling tiles. The HVAC system is designed to ensure proper air pressure differentials to prevent contamination from outside the clean room. Lighting systems are also designed to minimize the generation of particles.

Food Packaging

Clean rooms used in food packaging typically require an ISO Class 5 or better level of cleanliness. The construction of clean rooms for this application involves materials such as vinyl flooring, aluminum walls, and ceiling tiles. The HVAC system is designed to ensure proper air pressure differentials to prevent contamination from outside the clean room. Lighting systems are also designed to minimize the generation of particles.

It is important to note that the construction of clean rooms for each application can vary based on the specific requirements of the industry and the regulatory standards that must be met.

Choosing the Right Clean Room Construction Company

To ensure you have the most positive outcome when selecting a clean room construction company, it is important to compare several businesses using our directory of clean room construction companies. Each clean room construction company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each clean room construction business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple clean room construction companies with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services